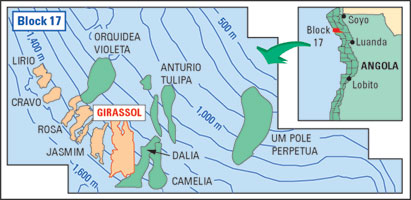

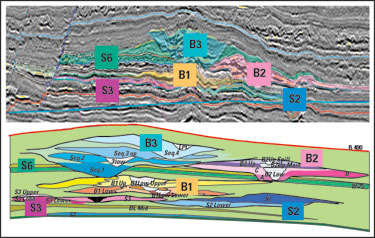

Geophysics/ 4DOptimizing development of Angola’s Girassol fieldTotal utilized 3D/4D seismic and other new reservoir and production testing technologies to update development of a huge deepwater field.In the following article, authors from Total E&P Angola, the field operator, describe key elements in a multi-technology application to update development of this deepwater field first initiated in 1998. The critical reservoir model needed to plan optimum development of this major field with an estimated 1.5 billion bbl (Bbbl) oil-in-place was built and updated by 4D seismic, downhole measurements, tracer injection, production logging and other technologies. Girassol development, with seafloor wells flowing to a floating production system, is being supplemented by the associated Jasmim field, with three other offsetting fields development in future plans. INTRODUCTION The Total-operated Girassol field located in Block 17, offshore Angola, is a deep offshore field in water depths ranging from 4,100 ft to 4,590 ft (1,250 m to 1,400 m), Fig. 1. The field was discovered in May 1996 with the GIR-1 well and was appraised later with three additional wells. The Girassol system comprises three main turbiditic faulted channel complexes eroding underlying complexes, and thinner sheet-like deposits. Sand juxtaposition also exists across the faults, Fig. 2.

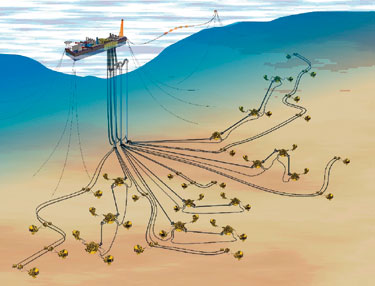

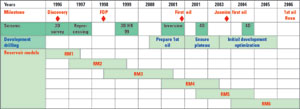

Development of Girassol was decided in 1998. It took place in three phases with data acquisition and drilling rig activity adapted to each phase. A high-resolution 3D seismic (3DHR) was carried out in 1999, and two repeat 3DHRs (4D 2002, 4D 2004) were completed one year and three years after first oil, to monitor gas injection and options for future infill drilling. The planned sealine layout comprises a two-well manifold system linked by insulated flowline bundles, Fig. 3. The layout lends flexibility in well planning, integration of acquired data and new technologies. The manifold concept allows trajectory optimization for multi-target, high-angle wells for the relatively shallow Girassol reservoirs.

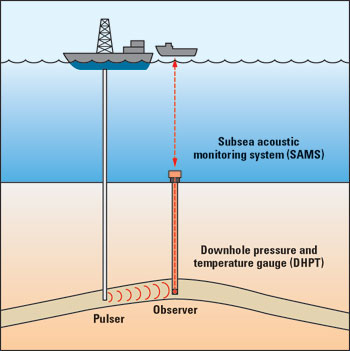

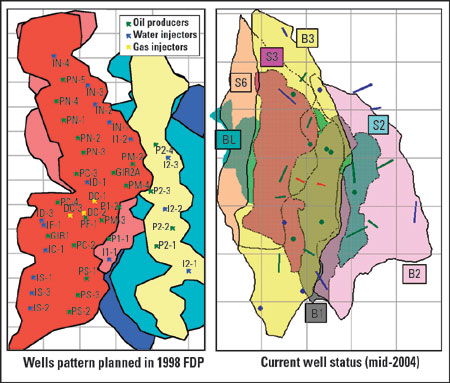

Excellent reservoir properties and good communication within B3 Complex have been established through DST, MDT (Modular Dynamics Tester) and interference testing. Water injection and produced gas re-injection started several months after first oil. The reservoir pressure reacted efficiently to injection. Well performance and reservoir performance, in general, have been better than expected. Produced gas is re-injected into the main complex in two gas injectors drilled in the central area. De-sulphated seawater injection started in May 2002 for reservoir pressure maintenance and sweep efficiency. Both water and gas breakthroughs have occurred in several wells. Data acquired both before and after first oil have been used to mitigate reservoir risk by building better reservoir models. The well placement has evolved with the availability of qualified improved technology and integration of acquired data. The well count for the initial development has been reduced by eight with respect to the 1998 development plan. To optimize reserves, identify, locate and optimize infill targets, the data acquisition program has been adapted to the production phase. INITIAL DEVELOPMENT The Girassol development was approved based on data available in 1998, i.e., 3D seismic shot in 1996, one exploration well and three appraisals. Oil-in-place was estimated at about 1.5 Bbbl. The oil quality of 32°API is close to Brent specifications. Initial plans called for 40 subsea wells: 23 producers, 14 water injectors and three gas injectors (to be converted to water injection at a later stage). Consistent with Total’s environmental policy and in line with Angolan authorities’ regulations, all associated gas is re-injected into the main reservoir, except internal consumption for fuel and safety flaring. Gas re-injection will continue until a pipeline is built for gas export. A fast-track approach was decided for this ambitious deep offshore project. Girassol, one of the largest deep offshore fields, was put onstream in December 2001, less than 5-1/2 years after discovery. This was followed by a ramp-up to a production plateau oil rate of 200,000 bopd reached by February 2002, well ahead of schedule. Well performance has been better than expected and production in 2003 averaged nearly 215,000 bopd. As a result of the fast track approach and limited available data, some significant uncertainties remained and needed to be addressed during development. The less risky and most prolific wells were drilled in 2001. The plan was to put the B3 complex on production first, then develop B1 with a program to mitigate major B1 uncertainties (presence or not of a channel-skin-like levee/channel communications) and to appraise B2 to the East. Communication between complexes was not considered in reservoir models at that time. DATA ACQUISITION Interference tests: Sealing potential of the faults was one of the essential factors to consider when defining well pattern. It was evaluated with different techniques using 3DHR data and seismic attributes, but the different results remained qualitative, with insufficient confidence to predict sealing potential of the main faults. It was decided to make a dynamic acquisition by performing interference testing in the B3 complex during the first development phase (before first oil), between wells separated by one or two major faults. Six tests were performed between an observation well and an active well (oil production or water injection). The observation well was equipped with the SAMS (Subsea Acoustic Monitoring System) designed to transmit downhole pressure records to surface, Fig. 4. Five tests were positive, showing that most of the faults were non-sealing.

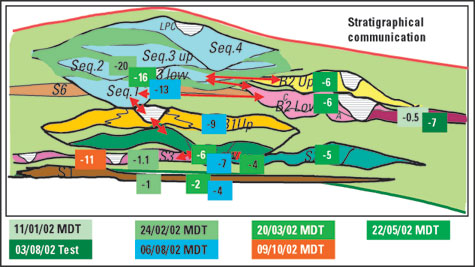

MDT: During the first year of production (with only the B3 complex producers onstream), MDTs were acquired in most of the newly drilled wells. The pressure measurements showed that all the other complexes and sheets were affected by the production start-up in B3, which meant that all the complexes are in communication through either erosion surface or faults, Fig. 5. The level of depletion from one complex to another also gave information on heterogeneity between the sand bodies.

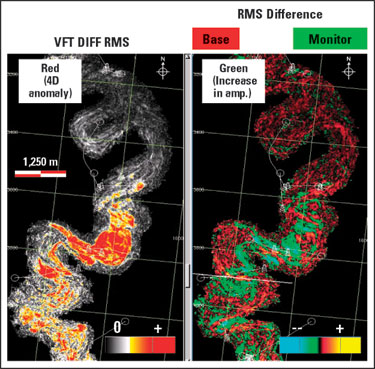

Downhole measurements: All the producers are equipped with permanent downhole gauges. This allows gathering pressure measurements during well testing (buildups), for static reservoir pressure monitoring and reservoir characterization. Transient behaviors are matched in fine-gridded reservoir models. Prior to well connection, SAMS is used to monitor static pressure and interference between wells. Temperature data permits the detection of breakthrough events. Intelligent completions (with adjustable downhole chokes) are installed on wells in the Jasmim field (Jasmim reservoirs are in communication with Girassol and are producing through the Girassol FPSO). 4D seismic: One year after first oil, and eight months after water and gas injection startup, 4D seismic was acquired. The objective was monitoring of the injected gas bubble extension. Analysis of discrepancies with the first 3D, shot three years before, allowed: observation of the gas bubble expansion resulting from gas injection at the top of the B3, rise of the water-oil contact in different complexes and sheets, and some heterogeneities not taken into account by the geological model, Fig. 6.

PLT: Two types of PLT (Production Logging Tool) acquisition have been performed, namely initial and monitoring. Initial PLTs are performed on multi-reservoir completed wells. In injectors, PLTs are mostly performed several months after start of injection. Monitoring PLTs are acquired to answer a specific development issue and/or for well behavior prognoses. Tracer injection: Interference testing before and after Girassol first oil has proven communication across faults; and MDT measurements have proven communication between complexes. Water breakthrough has been observed, but produced water chemistry has not been completely conclusive on the origin of produced water in wells. Injection of inert tracers is being implemented in a comprehensive effort to: optimize injected waterflow pattern and reservoir connectivity, and locate infill wells. RESERVOIR MODEL UPDATES Reservoir Models 1 to 3, Fig. 7, were based on exploration wells, and the 1996 3D seismic and its successive processings. Reservoir Model 4 was based on the 1999 3DHR that allowed a better stratigraphic reservoir description, as well as better architectural element characterization. In reservoir Model 4, data acquired from the first eight initial B3 development wells was integrated. It became increasingly evident early in the development process that inter-complex communication was playing an important role at Girassol. It became necessary to model inter-complex communications to minimize adverse effects on offset wells. Initial reservoir models built for each complex were connected in an attempt to model inter-complex communication.

Appraisal of B2 had shown it to be a much better and larger reservoir than initially mapped. The well pattern was adjusted, thanks to flexibility inherent in the initial well pattern. A new version of Model 4 was built and used to develop the B2 reservoir. The model was history matched with production data available at that time. This model showed that, out of the initially planned 40 wells, only 32 were required for the initial development, Fig. 8. Intensive use of horizontal wells was implemented along with the data acquisition, establishing good vertical communications. Today, a new reservoir Model 5 integrates both improved static data (seismic inversion from 1999 3DHR, results of 25 development wells) as well as two years of production history.

In this new model, all Girassol complexes have been included in the same grid, and inter-complexes communication has been modeled explicitly. Smaller sheet-like deposits are also included, resulting from the higher seismic resolution. This model confirms plans for the initial development and provides a better flow pattern understanding. This model is being used to study gas management and waterflood optimization, and optimize location of the few wells left before initial development closeout. A newer reservoir Model 6, including Girassol and Jasmim reservoirs, is being constructed. It will take into account all learnings from the 2002 4D seismic. Another 4D was acquired in November 2004 to monitor water movements as well as identify and optimize potential in-fill future well targets. And for ullage* optimization, after Jasmim reservoirs were put onstream in November 2003, it is planned to tie in Rosa, Cravo and Lirio fields to the Girassol FPSO for ullage filling. Optimizing the timing of these developments and remaining expenditures of Girassol/ Jasmim is a major challenge for the reservoir models.

|

|||||||||||||||||||||||||||||||||||||||||

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Driving MPD adoption with performance-enhancing technologies (January 2024)

- Digital transformation: A breakthrough year for digitalization in the offshore sector (January 2024)

- Offshore technology: Platform design: Is the next generation of offshore platforms changing offshore energy? (December 2023)

- 2024: A policy crossroads for American offshore energy (December 2023)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)