Completions/ Stimulation Technology

Mature Colombian field improved with dual stimulation

A combination of acid and propped fracturing technologies generated a significant increase in production and reserves, where hydraulic fracturing had failed.

Rafael Rozo and Javier Paez, Petrominerales; Art Milne and Diego Soler, Schlumberger

Colombia’s Orito field has operated for more than 35 years. By this decade, it had seen production decline to less than 3,500 bopd from a one-time peak of 66,000 bopd. Recently, Petrominerales achieved a significant increase in production and recoverable reserves by using a dual stimulation service that combines acid and propped fracturing technologies.

The treatment was successfully used in a reservoir that has frequently failed to respond to hydraulic fracturing, and where a 2002 third-party reservoir study concluded that the wells "indicate higher skin factors following the fracture treatment and lower production ratios, regardless of the fluid used." The service is designed to remove fracture face skin and optimize fracture conductivity.

ORITO FIELD AND CABALLOS FORMATION

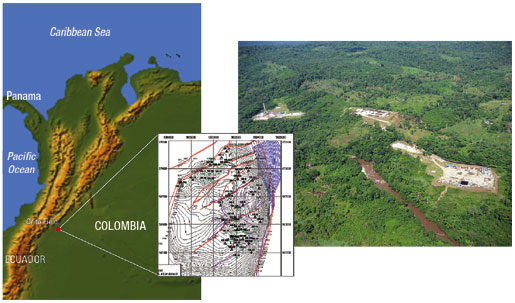

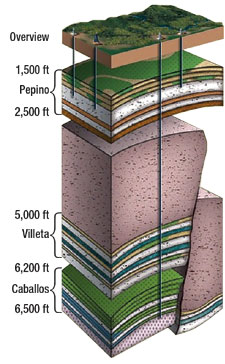

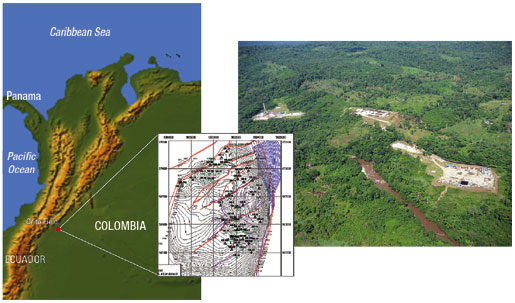

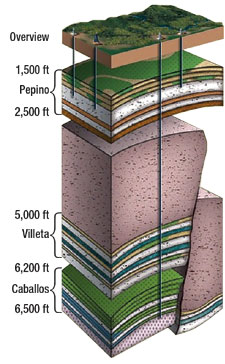

Orito field, almost 17 mi2 (43 km2) in area, is in Colombia’s Putumayo basin, Fig. 1. As the basin’s largest field, it originally contained more than 1 billion bbl of oil-in-place, in three primary reservoirs. The most significant is the Cretaceous Caballos formation, a complex series of fluvial/ deltaic and marginal marine sands that originally contained more than 700 million bbl of oil-in-place, Fig. 2. The Caballos zone, alone, has produced 186.7 million bbl since the field was discovered in 1963. By 2005, the reservoirs had cumulatively produced 226 million bbl, or about 22% of original oil-in-place.

|

Fig. 1. Orito field is in the Putumayo basin of southern Colombia.

|

|

|

Fig. 2. The Cretaceous Caballos formation is a complex series of fluvial/ deltaic and marginal marine sands.

|

|

To increase production, Petrominerales developed a plan that included well recompletions, infill drilling and hydraulic fracturing. The extent of the infill drilling program depended on the production increase achieved from recompleting and stimulating existing wells. Although hydraulic fracturing was an integral part of the plan, results of the initial conventional treatments were unsatisfactory and confirmed earlier.

COLLABORATION

Previous treatments had employed conventional propped fracturing methods using various oil- and water-based frac fluids. To find a new technically and commercially viable way of performing propped fracturing in the Caballos reservoir, Petrominerales assembled a team of personnel from its own ranks, from Schlumberger and from Instituto Colombiano del Petroleo (ICP), Ecopetrol’s research laboratory. The team brought together experts in stimulation fluids, completions, rock mechanics, geology and reservoir engineering.

Since prior fracturing treatments were executed as per design, fluid/ fluid incompatibility or fluid inefficiency was not considered the most likely reason for the less-than-expected production response. Thus, a series of core flow tests was conducted to evaluate the formation response to different fracturing fluids, including oil-based and polymer-free water-based fluids. Additionally, the fluid/ fluid compatibility was evaluated and optimized.

Results of the initial core flow testing showed that regardless of the type of frac fluid used, retained permeability after a static leakoff test was less than 5%. This information was used to calculate the expected fracture face skin and resulting reduction in productivity index (PI) after a hydraulic fracturing treatment.1,2,3 The calculated PI reduction proved similar to that historically observed. Parallel to this analysis, Petrominerales worked with ICP to review historical laboratory reports from prior years of field operation.

Normally, formation clays form a layer that lines the pore spaces. However, evidence found in the Caballos reservoir showed that kaolinite clays and mica were effectively free in the pore spaces. This was consistent with extremely low critical velocities (+/ – 1 ml/min) and much lower-than-expected spurt loss values seen during core flow testing.

The findings led the team to conclude that fluid flowing through pore spaces carried the clays into the pore throats, effectively choking them. This explains why the PI on a number of wells actually declined after conventional hydraulic fracturing. The solution contemplated a mix of matrix acidizing and propped fracturing technologies to allow for:

- Dissolution, or a significant reduction in size of the clay particles

- Efficient placement of the proppant without damaging the formation.

As a result, a series of acid response tests were conducted with a variety of reactive systems to evaluate stimulation response, change in critical velocity and improvement in retained permeability after exposure to a fracturing fluid. Testing showed that the selected reactive fluid systems greatly increased retained permeability (>30%) and would not damage the formation. Final selection of the reactive fluid system was further evaluated by research engineers in ICP and modeling, using geochemical simulation software.

Because of the formation permeability (50 – 200 md), it was necessary to viscosify the reactive fluid to create a hydraulic fracture with a geometry similar to that of the final propped fracture and so ensure that all fracture surface areas were treated. By using viscoelastic surfactant gelling agents, it was possible to create a viscous reactive fluid capable of creating a hydraulic fracture and removing clays from the matrix of the fracture faces. Using a polymer-free fracturing fluid followed by a low-guar polymer fluid also achieved excellent results for retained matrix permeability when tested by ICP.

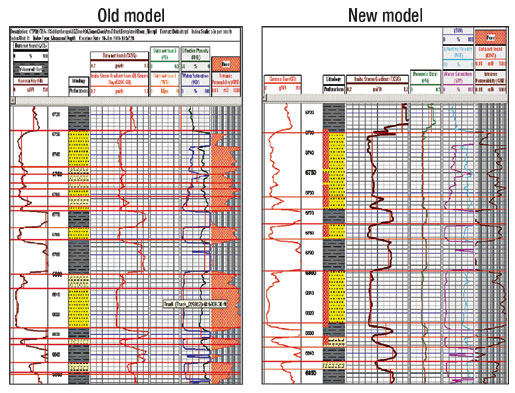

A key element of the team’s work was the collaborative effort to develop an updated reservoir model of the Caballos formation. The model enabled identification of the wells and zones that would respond best to hydraulic fracturing.

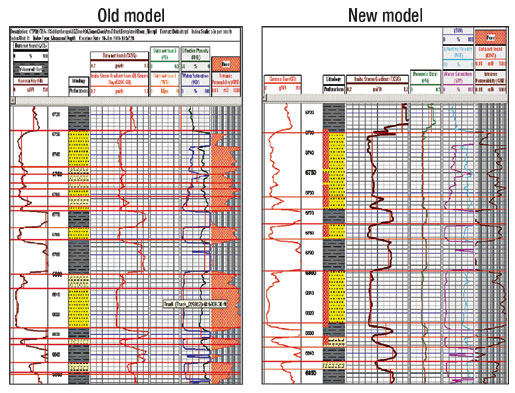

Furthermore, the team developed a geomechanical model that is continually updated. This enables Petrominerales to optimize the number and size of hydraulic fractures in each well, Fig. 3.

|

Fig. 3. The change in stress contrasts with the old and new geomechanical models.

|

|

DUAL STIMULATION

The reservoir model and well analysis was used to rank potential candidate wells and select those to receive hydraulic fracturing. Existing wells selected as candidates were those with:

- High historical production, but recent indication of a reduced PI.

- Low-to-medium productivity and low risk of breaking into gas and water zones.

The selection process consisted of mapping iso-volumes of oil, gas and formation water in place and superimposing accumulated volumes of produced oil, gas and water for each well. Depths of the producing intervals were then matched to current gas-oil and water-oil contacts. Geomechanical stress profiles were then reviewed to aid design.

A pseudo-3D, fracturing design simulator was used in most treatments to optimize the size and number of fractures. After the dimensions of the final propped fracture were established, the volume of the engineered reactive fluid was determined, based on the fracture face surface area and the estimated fluid efficiency of the reactive fluid. Optimization during the project has shown that a definite minimum volume of reactive fluid is required to perform the calibration treatment, which in the Caballos formation, is sufficient fluid to provide 12 in. of penetration into the fracture face matrix. Fluid efficiency is adjusted to ensure that both the required fracture geometry and volume/ft2 are obtained when modeling the treatment. At this point, the volumes of fluid and proppant were determined as for a conventional propped fracture treatment.

Experience has shown that the required pad fluid volume is in the order of 40% to 50% of the total clean fluid volume, depending on the height of the intervals, to achieve an 80-to-150-ft fracture half-length. The pad’s fluid efficiency is less than expected, due to the reactive fluid increasing the effective permeability of the fracture faces and the breaking effect of the reactive fluid on the gels. This is in stark contrast to the experience of other operators, who frequently report that the fluid efficiency during the main treatment is considerably higher than the level determined from the calibration treatment. These results are further evidence of the "plugging" phenomenon observed during core flow testing.

The maximum proppant concentration used is 6 ppa of 16/20 ceramic proppant, with the design calling for an aggressive tip screenout to maximize fracture conductivity. The proppant volume pumped per stage varied between 20,000 and 50,000 lb, depending on the treatment design, while pump rates varied from 15 to 21 bpm with maximum surface pressure of 8,000 psi.

Initial treatments were done by pumping the calibration treatment using customized dual stimulation fluid, after which the hydraulic fractures were allowed to close prior to pumping the main treatment, Fig. 4. A planned improvement to this procedure is to use a reactive fluid as the pre-pad or pad ahead of a sand-laden, solids-free, visco-elastic fluid in what is otherwise conventional propped fracturing. The use of a visco-elastic fluid as the main treating fluid eliminates any loss of fluid efficiency, due to premature breaking of a conventional crosslinked polymer fracturing fluid.

|

Fig. 4. Stages in a typical dual stimulation treatment.

|

|

PRODUCTION AND RESERVES

The DualSTIM service, performed on the Orito 20 well in the Caballos reservoir, resulted in a PI increase of 0.5 to 0.7 bopd/psi and exceeded pre-treatment predictions. Following this, over the next three months, the same treatment system was used on seven additional wells. On many of them, the production and PI increases also exceeded predictions.

The increased production of the eight wells treated during a pilot program ranged from 50% to 1,000%. The positive results, together with potential in some undrained areas, have encouraged the company to extend the pilot project and initiate an aggressive infill drilling program in 2006 – 2007.

Prior to these treatments, field production was less than 3,500 bopd. After drilling two new wells and performing a number of planned interventions and re-completions – including 10 dual stimulation treatments – output increased to 5,800 bopd. Average PI for these wells was 0.58 bopd/psi compared with an average 0.28 bopd/psi for existing wells.

Based on results from these jobs, completed in less than six months, Petrominerales plans to extend the field pilot project to encompass as many existing wells as feasible. So far, the firm has identified 10 to 15 additional candidate wells, and predicts an average 70-to-150-bopd/well increase.

In addition, the company has launched a 20-to-30-well infill drilling program over the next two years, incorporating dual stimulation as part of completions. The first newly drilled wells completed with dual stimulation came on production at about 1,000 bopd, compared with 150 to 400 bopd for previous new drills.

The most recent third-party reservoir study in December 2005 concluded that the recoverable reserves for Petrominerales in the Orito and Neiva fields were 70% higher than originally estimated. This was, in part, due to increased production achieved using dual stimulation in existing Orito wells. Production from new Orito wells receiving these treatments has resulted in a further 9% increase in estimated recoverable reserves.

Dual stimulation applied by Petrominerales in the Caballos reservoir at Orito field has helped to achieve a significant improvement in production levels and an independently verified increase in recoverable and estimated recoverable field reserves. This has turned an aged brown field with steadily declining output into a growth asset driven by workovers of existing wells and aggressive development drilling.

Petrominerales hopes that when field redevelopment is completed, it will result in a more than five-fold production increase. With these treatments’ success, potential exists for expansion of this acidizing and hydraulic fracturing technology into other reservoirs.

LITERATURE CITED

1 Cinco-Ley, H. and F. Samaniego-V, "Transient pressure analysis: Finite conductivity fracture versus damaged fracture case," SPE paper 10179.

2 Adegbol, K. and C. Boney, "Effect of fracture face damage on well productivity," SPE paper 73759.

3 Romero, J. Diego, Peter P. Valko, and Michael J. Economides, "The optimization of the Productivity Index and the fracture geometry of a stimulated well with fracture face and choke skins," SPE paper 73758.

|

THE AUTHORS

|

|

Rafael Rozo is chief engineer for Petrominerales Colombia Ltd, responsible for optimizing production at various fields. He has more than 15 years of experience with several service and operating companies in Colombia and South America. Mr. Rozo earned a BS degree in petroleum engineering from the University of America, Bogotá, and an MBA from the University of Los Andes.

|

|

|

Javier Páez is a senior reservoir engineer for Petrominerales Colombia Ltd. Prior to taking this position, he worked for Ecopetrol for more than 12 years in workover, production and reservoir engineering, covering different Colombian basins. Mr. Páez earned a BS degree in petroleum engineering from the University Industrial of Santander (Colombia).

|

|

|

Art Milne is a geomarket technical engineer for Schlumberger Well Services. In his 26 years with the company, he has held a variety of technical and marketing positions in North and South America, and the Middle East and Far East. His expertise covers stimulation, sand control, cementing and coiled tubing services. Mr. Milne earned a geology degree from the University of Edinburgh in 1979.

|

|

|

Diego Soler is a stimulation technical engineer for Schlumberger in Bogotá, Colombia, responsible for developing engineered solutions to improve productivity. He has more than 10 years of experience with Schlumberger in various operational, technical and marketing positions. Mr. Soler earned a BS degree in petroleum engineering from the University of America, Bogotá.

|

|

|