Topics ranging from the advances of deepwater drilling technology to new designs in the LNG industry will pack this year’s OTC schedule.

Krista H. Kuhl, Technical Editor

OTC 2008 promises to continue expanding and improving as the world’s premier event for the drilling, exploration, production and environmental protection of offshore resources. This year’s theme, “Waves of Change,” reflects the industry’s transition as project scopes and parameters are stretched to fulfill ever-increasing demand.

OTC quick facts. As in previous years, OTC will be held in Houston, May 5-8, in the Reliant Park complex. More than 67,000 people visited OTC 2007-a 25-year high and an increase of 13% over 2006.

In 2007, OTC’s exhibition expanded for the first time into the adjacent Reliant Stadium and added more outdoor exhibit space. Nearly 2,400 companies from more than 30 countries participated in the show. Total exhibit space was nearly 530,000 square feet.

Awards Luncheon. James Ray, who retired from Shell in 2005 and is currently president of Oceanic Environmental Solutions in Spring, Texas, will receive the 2008 OTC Distinguished Achievement Award for Individuals during the Awards Luncheon on Tuesday, May 6. Additionally, StatoilHydro will receive the Distinguished Achievement Award for Organizations. The keynote address will be delivered by Jesús F. Reyes-Heroles, director general of Petróleos Mexicanos (Pemex).

|

|

James Ray, OTC Distinguished Achievement Award recipient.

|

|

|

Ray will be recognized for his leadership in demonstrating how the petroleum industry can operate in harmony with the environment and for his rigorous pursuit of science related to the effects of oil and gas industry operations on marine ecology.

StatoilHydro will receive the award for companies, organizations and institutions for its Ormen Lange project, an innovative subsea-to-shore development that overcame significant technical challenges to become Norway’s deepest offshore venture.Two Heritage Awards will also be presented at the 2008 Awards Luncheon to Pierre-Armand Thomas, senior vice president of technology, innovation and risk management for Technip; and Gordon Sterling, who had a 35-year career with Shell Oil Company and served as 1998-1999 chairman of the OTC Board of Directors. The Heritage Award recognizes individuals who have provided distinguished service and significant contributions to the development of offshore resources.

|

|

|

Heritage Awards recipients Gordon Sterling (left) and Pierre-Armand Thomas (right).

|

|

|

Topical luncheons. A variety of topical luncheons will be given this year, offering attendees the chance to hear leading experts discuss such issues as production, development, research and technology. Space is limited, so it is recommended that participants buy tickets for the topical luncheons in advance. The four luncheons on Monday, May 5, are “Offshore oil and gas turns 70: Is rust more evil than depletion,” “US offshore oil and gas production: Its impact-present and future,” “China offshore: Technical challenges, perspective and cooperation opportunities” and “Canada’s next offshore natural gas development.”

There will be three luncheons on Wednesday, May 7: “Sustainable strategies for staffing the energy industry,” “Industry and government model for ultra-deepwater technology research, development, demonstration and commercialization” and “Lower Tertiary: A new wave of change in ultra-deepwater Gulf of Mexico.”

The three topical lunches for Thursday, May 4, will be “Methane hydrate challenges and future,” “How is LNG changing the natural gas markets in North America?” and “Improving US energy policy through better dialogue between consumers and the energy industry.”

Industry breakfasts and morning reports. OTC joins forces with the US Department of Commerce to offer expert views on business practices in developing regions during breakfast sessions. For 2008, the selected regions are China, Indonesia and Qatar. Because seating is limited, you are encouraged to purchase tickets in advance. On Tuesday, May 6, Chinese officials will highlight commercial opportunities and investment policies in China’s offshore oil and gas sector in their presentation, “Commercial opportunities in China’s offshore oil and gas sectors.” In addition, panelists from US companies will discuss their operations in China and perspectives on China’s offshore opportunities.

Executive-level Indonesian government and industry representatives will give the presentation “Indonesia: Exploring new offshore and frontier opportunities” on Wednesday, May 7. They will discuss Indonesia’s oil and gas production and exploration activities, with a focus on upstream investment needs and opportunities for international energy companies.

Finally, on Thursday, May 8, the topic “Commercial opportunities in Qatar’s offshore oil and gas sector” will be discussed by Qatari officials. This forum will highlight commercial opportunities and investment policy in Qatar’s offshore oil and gas sectors. In addition, panelists from US companies will discuss their operations in Qatar and their perspectives on the oil, gas and LNG sectors.

Building on the success of the 2007 “Morning Reports,” the program will again be held in 2008 on Monday, May 5, from 7:30 to 9 a.m. This session will present the unique challenges faced in developing BP’s Block 18 in Angola.

General sessions. Two general sessions will take place at the 2008 OTC. The first will occur Tuesday, May 6, from 2 to 4:30 p.m., covering “Petroleum-Energy of the future.” Panelists will discuss the supply and demand challenges facing the oil and gas industry. On the supply side, the oil peak, the rise of national oil companies, technology, the environment and strained resources will be considered. From the demand side, issues such as biofuels, air quality, climate change, trade pattern shifts toward Asia and the role of emerging economies will be discussed.

The second session, “Global energy outlook-What are the challenges?,” will take place Wednesday, May 7, from 2 to 4:30 p.m. Panelists will explain the nature of the energy challenges and share their views on what is required of the public and private sectors to deliver affordable and sustainable energy for the future. This panel will discuss development of new technologies that enable discovery of new energy resources, enhance oil and gas recovery, and reduce finding and development costs; rising project development costs; environmental concerns from growing CO2 concentration; and skilled-labor shortages in the industry. The session moderators will be Ahmed Hashmi of BP and Melanie Kenderdine of MIT. A panel representing BP, Baker Hughes, Schlumberger, the US Congressional Energy Committee and the US Department of Energy will participate.

Next Wave program. The Next Wave program is designed for upstream professionals under age 35 or those interested in meeting them. The program will open Wednesday, May 7, with a general session from 8:30 to 10:45 a.m., featuring speakers Karl Kurz, chief operating officer at Anadarko; Ryan Lance, president for E&P of Europe, Asia, Africa and the Middle East at ConocoPhillips; and Pete Miller, chairman, CEO and president of National Oilwell Varco. They will share their viewpoints on the changing roles of service companies and independent oil companies at a time when national oil companies hold more of the proven reserves than ever before.

Following that session, there will also be a panel session from 11 to noon. “My career-The key themes impacting my future role in the industry” will be moderated by Chris Ross, VP of CRA International, with panelists Amin H. Nassar, business line head for E&P at Saudi Aramco; John Rose, upstream president of KBR, and Chris Haver, DeepStar director and VP for the Ultra-deepwater Technology Program at Research Partnership to Secure Energy for America. They will discuss how the evolution of the industry will affect the decisions individuals have to make about their careers and the paths they take.

After a group lunch, the afternoon will offer Next Wave participants more than 30 roundtable discussions from which to choose, lasting from 1:30 to 4:30 p.m. Each breakout is to be facilitated by industry experts giving attendees the opportunity to share best practices, brainstorm solutions, discover resources and address current issues and trends with peers from around the world.

Technical program. Throughout the conference, more than 300 papers will be presented during the technical sessions. A sample of the topics includes:

- Compressed-air breathing apparatus for helicopter underwater evacuation

- Kikeh development: Sand control selection, design and implementation of ESS

- Laboratory investigation of oil-swelling elastomers for smart wells

- Managing fatigue in deepwater flexible risers

- Managing flow assurance and operational risks in subsea tieback systems

- Developing hydrate monitoring and early-warning systems

- Estimation of thermal properties of methane-hydrate sediment.

A listing of the major technical session topics is located in Table 1. For a more detailed listing of individual papers in the technical program, please check the listings at http://www.otcnet.org/2008/technical/index.html.

TABLE 1. OTC 2008 technical sessions

Click image to enlarge table |

|

|

Spotlight on New Technology. Now in its fifth year, this program will recognize 14 technologies representing 11 companies: ABB AS; Baker Hughes Inc.; Cubility; Delmar Systems, Inc.; Expro; FMC Technologies, Inc.; Schlumberger; Versabar, Inc.; Weatherford; Welltec; and Yantai Raffles Shipyard Ltd.

Winners are selected on four criteria. First, the technology must be new and innovative; i.e., less than two years old. Second, the item must have been proven through either prototype testing or full-scale application. Third, it must have broad interest and appeal for the industry. Finally, the technology must make a significant impact, providing sizeable benefits beyond existing technologies. WO

Cement automatically repairs casing, and injection control device increases oil recovery

Schlumberger was recognized for two new technologies this year. One award was for the company’s FUTUR active-set cement technology, which has the unique ability to automatically self-heal in the presence of hydrocarbon leaks through cracks or microannuli created by post-completion changes in the regional stress field. Cyclical pressure or temperature regimes can cause changes in casing stress that damage the hydraulic integrity of well cement, often years into production or even after abandonment. But if the well has been treated with the active-set cement, any resulting leaks will be repaired automatically, without any need for intervention from surface.

|

|

Schlumberger’s ResInject injection control device.

|

|

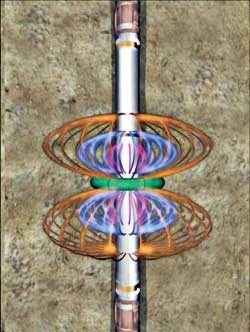

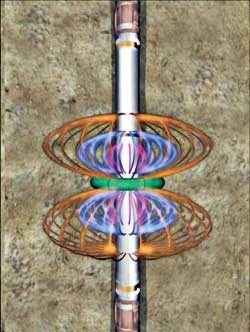

Schlumberger also received an award for its ResInject injection control device, which provides a solution to a vexing problem using an innovative application of fluid dynamics principles. By removing the flow-control interface from the screen surface to a controlled environment, the flow regime is changed from the traditional Darcy spherical flow shape factor to Bernoulli flow, which is viscosity independent. Using configurable ceramic nozzles to control injection fluid flowrate, the pressure drop across the system can be designed for the zone to be treated. As a result, low-permeability zones receive more injection fluid than those treated using a normal screen configuration, thereby increasing ultimate oil recovery.

Baker Hughes Inc. receives two Spotlight awards for the third consecutive year

Baker Oil Tools received an award for its RAM Rotatable Self-Aligning Multilateral System. The system offers a solution for extended-reach multilateral wells where getting liners to the bottom may require continuous rotation. The system is the first-and thus far, only-multilateral system that allows continuous rotation of the lateral liner while simultaneously and reliably landing a completion system that can mechanically support the lateral junction.

|

|

Baker Oil Tools’ RAM Rotatable Self-Aligning Multilateral System.

|

|

The system delivers reliable multilateral junctions for widely-used Level-3 and Level-5 completions. It provides mechanical support for, selective control of, and access to all lateral junctions that join cased and cemented main bores with screened or lined openhole laterals in wells with commingled production.

The system was first successfully installed on Alaska’s North Slope in 2007. An offshore installation is pending in the North Sea in early 2008, followed by applications in the Middle East.

Inteq, a division of Baker Hughes Inc., received an award for its MagTrak technology. This technology is an LWD tool that provides a comprehensive range of magnetic resonance answer products, including formation porosity, bound-fluid volume, free-fluid volume, permeability, hydrocarbon detection and T1 and T2 distribution spectrums. The porosity measurement is not dependent on formation lithology, being based upon magnetic resonance technology, and the service does not require a radioactive source. The service is available as a standard 6¾-in. collar-based tool, fully combinable with rotary steerable systems, and can be utilized in borehole diameters from 83/8 in. to 97/8 in.

|

|

INTEQ’s Magtrak LWD tool.

|

|

MagTrak delivers real-time T2 distributions. These real-time answers empower the asset team to become more influential in the decision-making process to optimize wellsite efficiency, safety and hydrocarbon recovery. Real-time applications and benefits include identifying potential borehole problems by clay typing, earlier input to improve perforation programs based on permeability index, identifying missed pay in low-resistivity formations, geosteering into production “sweet spots” and obtaining high-quality data in high-risk wells.

Openhole liner system and cutting tool mitigate hazards

Weatherford received two Spotlight awards this year. One award was for its MetalSkin monobore openhole liner system. This system reduces installation risks, minimizes well construction costs and mitigates drilling hazards. The system eliminates the slimming of a well profile during well construction to improve well productivity and reservoir recovery. An oversized shoe is run into the hole with the previous string of casing. After it is installed at the bottom of the previous casing string, the oversized shoe can be drilled out with conventional bottomhole drilling assemblies.

|

|

Weatherford’s MetalSkin monobore openhole liner system.

|

|

Once the next hole section is drilled, the expandable liner extension is run to total depth of the well and expanded back into the oversized shoe. This technique provides an expanded string of casing with the same drift as the previous casing string; therefore, a string of casing is gained with no loss of hole size.

The design provides a full bore in the overlap between the monobore openhole liner system and the parent casing string, reducing operational risk by eliminating the need to over-expand the shoe track to receive the expanding MetalSkin system.

Weatherford received a second award for its Motorized Cutting Tool (MCT). The MCT cuts downhole tubulars without the use of dangerous chemicals or explosives and facilitates fishing by displacing tubing cleanly, whether in tension or compression, with no flaring and no debris left in the well. The tool is capable of making multiple cuts in challenging environments and operating globally without the need for special licenses for transportation, storage or usage.

Camera increases operator’s visibility downhole

Expro received an award for its ViewMax side-view camera. This versatile camera allows the operator to switch between a traditional down view to a new side camera with the flick of a switch. The entire camera will then rotate 360º on its motor section to enable a full investigation.

The camera can provide more information to help operators make remediation decisions, particularly in wells with suspected casing damage. By providing images of the pipe wall, the camera can provide operators with more information on the causes of failures in their well.

The ViewMax incorporates a second camera, Expro’s downhole video backlight. The second camera is pointed sideways and rotates, allowing unobstructed and undistorted views of the wall of the pipe or openhole formation.

Anchor enables loading versatility

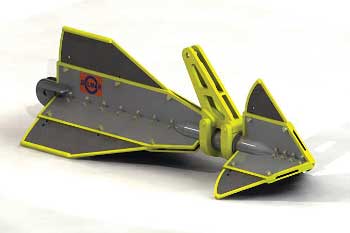

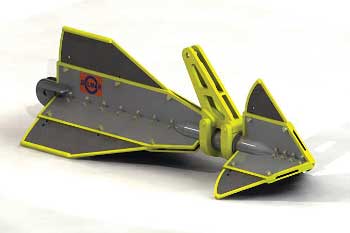

Delmar Systems Inc. received an award for its OMNI-Max Anchor. The anchor is a gravity-installed Vertically Loaded Anchor (VLA) for MODU moorings that offers unique performance characteristics not found in other deepwater anchor foundations. The OMNI-Max is capable of being loaded in any direction, 360° around the axis of the anchor. Under extreme loading and uplift angle conditions, the anchor will penetrate deeper into the soil to gain the needed capacity.

|

|

The OMNI-Max Anchor in the field.

|

|

|

|

The OMNI-Max Anchor by Delmar Systems can be loaded in any direction.

|

|

This anchor offers benefits to the design of mooring systems that reduce risk to subsea infrastructure in the event of station-keeping damage or failure. This technology may also allow damaged moorings to survive longer in the event of multiple line failure, since the load angle can change without the capacity of the foundation being adversely affected.

Bit drills and removes cuttings

Welltec won for its Well Miller Circulating Bit (CB), best described as a tunnel power drill. The Well Miller CB is able to establish full flow conditions by drilling through even the hardest materials. The novel drill has the unique ability to both drill out and remove cuttings to surface.

|

|

Welltec’s Well Miller ccirculating bit.

|

|

It is operated in conjunction with the Well Tractor that provides WOB and controls the reactive torque of the drilling process. The tool consists of a Basic Rotational Unit (BRU) including electronics, pressure compensator and electric motor sections. The BRU drives an impeller, which creates the vacuum flow to circulate through the liquid environment tool “dragging” sand into the 0.5-in. intake holes where it will deposit in the sand trap bailers. Depending on the configuration of the tool, a different number of bailer sections can be mounted.

Interventions can be performed in a rig-less environment, and with its unique ability to operate localized with E-line depth control, the Well Miller CB ensures that wells are quickly restored to production.

Lift system provides control during heavy-lifting operations

Bottom Feeder, a new heavy-lift system designed, built, and operated by Versabuild, an affiliate of Versabar, received a Spotlight award. The Bottom Feeder retrieved six hurricane-toppled platform topsides from the seabed in 2007. Each of the eight-leg topsides was retrieved as single lifts, with peak lift weights of up to 1,600 t. The decks were set onto cargo barges and scrapped onshore. This approach, compared to small-piece removal, results in reduced personnel exposure offshore and is extremely cost-effective.

|

|

Versabar’s new heavy-lift system, the Bottom Feeder.

|

|

This new lift system has a rated lifting capacity of 4,000 t. The technology has a number of unique features that make it well-suited for heavy-lifting salvage operations. Four independent lift blocks provide an excellent degree of control during lifting operations, an essential requirement when lifting large, unbalanced structures where accurate weight data is not available, as well as structures resting on the seabed at varying unlevel degrees. As an example, some of the lifts for the system included topsides sitting upside down on the seabed.

Wireless sensor alerts operators of abnormal vibrations

ABB AS received a Spotlight award for its Wireless Vibration Sensor, a cost-efficient, high-quality sensor unit that communicates its measurements wirelessly to a central unit. The small, autonomous sensor unit is mounted onto a motor and comprises a vibration sensor (accelerometer), a temperature sensor and the means for wireless communication to a central computer. In turn, the computer system performs the necessary data analysis and storage and makes the data available to potential users.

|

|

Wireless Vibration Sensor by ABB AS.

|

|

The sensor is cylindrical with a diameter less than 1.5 in. and a height of less than 4 in. It has a threaded hole on the bottom for mounting on a motor close to a bearing. The shape and size are similar to traditional rugged wired accelerometers used in the industry. The frequency response of the device should be flat up to 10 kHz, making the device ideal for early detection of bearing failures.

The data is communicated over the air using the recently approved Wireless HART standard, securing interoperability with other products and systems. Data sent between the sensors and the central computer is authenticated and encrypted, thereby safeguarding the integrity of the system.

Vacuum provides better fluids separation

Cubility received an award for its Mudcube Vacuum, used for cleaning drilling fluids. The Mudcube rotates a continuous screen belt. It operates as a processing unit and gives the fluids and cuttings a milder treatment. No mechanical force is given to the screen, providing the fluids the best environment to be separated.

|

|

Cubility’s Mudcube provides enhanced fluids separation.

|

|

Ultrasound is transmitted to the drilling fluid on the rotating screen, and the bindings between the solids and the drilling fluid is broken. The return mud is transported on the screen belt and passes one or more apertures with a vacuum beneath the screen, which effectively sweeps the fluids through the screen and into a closed-loop fluid system. The vacuum degasses the fluid in the fluid system, and the gases are evacuated into the gas system. The solids are transported to the end of the belt path, where they fall off as a dry mass before leaving the machine.

Subsea ultra-deepwater completion system

FMC Technologies Inc. was awarded for its Enhanced Vertical Deepwater Tree (EVDT). A slimbore subsea completion system designed to provide large bore system capabilities, the EVDT can accommodate 7-in. tubing completions and pressures up to 15,000 psi within a 135/8-in. BOP stack, making it the industry’s most economic and versatile subsea completion system.

|

|

The Enhanced Vertical Deepwater Tree enables a small drilling rig to perform ultra-deepwater completions.

|

|

The EVDT allows ultra-deepwater completions to be performed from a small drilling rig containing the surface BOP, thus avoiding the need for expensive rigs during completion. The tubing hanger can be installed using a tubing head, or it can simply land into the wellhead, eliminating the tubing head. This allows for a more efficient installation when completion and drilling operations are conducted without retrieving the subsea BOP and riser.

The EVDT incorporates a retrievable flow module and flowmeter in its design, reducing production downtime for maintenance and meter replacement from days to hours.

Crane reduces work hazards in open sea

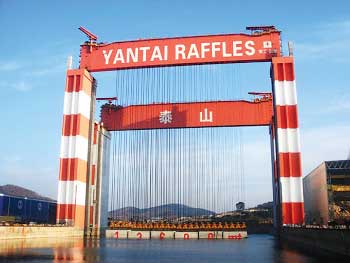

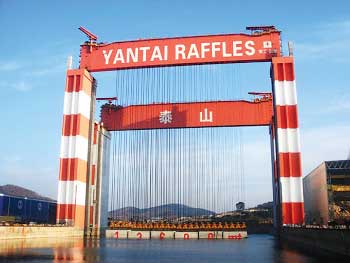

Yantai Raffles Shipyard Ltd. received an award for its Taisun, 20,000-metric ton (mt) gantry crane. Taisun is a unique lifting device that sits across a 380 × 120-m drydock. It is made up of two fixed beams placed horizontally across the dock floor on four columns. The beams, with lifting capacity of 10,000 mt each, are placed at heights of 89 m and 119 m, respectively. It has a lifting height of 83 m for its lower beam and 113 m for its higher beam.

|

|

Yantai Raffles Shipyard’s Taisun crane.

|

|

The installation of 96 unique lifting devices will enable the mating of an entire outfitted deck box of semi-rig onto its hull/pontoons in one activity, reducing work hazards at high altitudes and in the open sea. The one-day mating process, compared with conventional methods, will reduce both risks and time while improving quality significantly.

|