Long game: Reliable, interventionless completions for toe stages

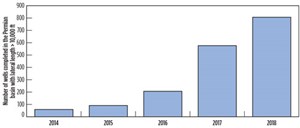

Once somewhat of a novelty, extended-reach laterals are now being drilled at an exponential rate across North America—including in the Permian basin. Over the last five years, the number of horizontal wells, completed with lateral lengths exceeding 10,000 ft in the prolific oil fields that make up this basin in West Texas and New Mexico, has increased nearly 12 times, jumping from 63 in 2014 to 813 in 2018, Fig. 1.

While longer laterals have provided operators with greater reservoir coverage, higher stage counts and, subsequently, higher production, it hasn’t come without challenges. One particular challenge is effective stimulation of the toe of the well. Operational challenges and risk arise when using tubing-conveyed perforating (TCP) for the first stage of completion operations, due to the nature of the extreme distance that the tools must travel downhole. Although interventionless, hydraulically activated sliding sleeves were introduced to solve this challenge, reliable opening has been an issue, and operators have been forced to run multiple sleeves as a precautionary measure.

Advances in hydraulically activated toe subs have greatly increased reliability to provide a more effective solution for stimulating the toe of the well. The success can be enhanced using hybrid completions that include ball-activated sliding sleeves to further expedite completion time and bring wells online quicker.

STIMULATION CHALLENGES

Plug-and-perf is by far one of the oldest completion methods. This method pre-dates horizontal wells, so the wireline deployment in vertical or slightly deviated wells relies on gravity for downhole conveyance. In horizontal wells, large volumes of water are needed to pump wireline perforating guns to depth, especially if there are doglegs and tight areas. If, for any reason, the tools become stuck, remedial mechanical or hydraulic tools require additional fluid.

Plug-and-perf tools also can be deployed, using coiled tubing (CT). One advantage of using CT for the toe stages is the ability to continually circulate fluid, which helps condition the well for smoother conveyance. On the other hand, a significant disadvantage of CT is its reach. Energized fluid, specialized metal-to-metal lubricants and tractors or agitators can help with conveyance; however, when pushing tools to depth, CT tends to spiral, due to cumulative friction.

If CT is pushed too hard, it can kink or buckle, causing the tubing to become stuck or part. CT generally should be treated with care, because any damage from over-pulling or fatigue leads to costly workovers. Sometimes CT is made with thinner or tapered walls to gain a lighter or longer spool, and thinner tubing is even more easily damaged. For long wells, these restrictions may leave the toe stages out of reach of CT.

CT intervention and its limitations are eliminated by ball-activated and hydraulically activated sliding sleeve technology. However, some hydraulically activated sliding sleeve designs fail to open consistently and present reliability concerns that limit their application. To address the issue, operators may run two or three hydraulically activated sliding sleeves at the toe of a well, to ensure at least one sleeve will provide access to the reservoir. While this option does allow for interventionless operations, it is not a cost-effective solution, especially when a high-pressure casing integrity test is required prior to stimulation.

Advances in hydraulic sliding sleeve activation technology resolve these reliability issues to enable stimulations in the toe of the well. In addition, the success of these tools further enhances long lateral completions, when combined with ball-activated sleeves in hybrid completions.

TOE SOLUTIONS

Packers Plus has engineered solutions to these challenges with a suite of hydraulically activated toe subs, Fig. 2. The Toe-XT testable hydraulic sleeve is an injection/production port that allows the casing string to be pressure-tested a single time before opening. After the casing integrity test has been performed and pressure in the well has been released, the sliding sleeve is ready to be activated, and the operator can begin stimulation operations immediately or at a future date.

The Toe-AP hydraulic toe sleeve is a sliding sleeve for the first stage of a cemented liner completion that reduces operational risk, while saving time and cost in delivering effective treatment. The sleeve is hydraulically activated and opens at a specific absolute pressure and the reliability of its operation is based on rupture disc activation.

A TREX rupture disc sub eliminates the need for a CT run to perforate the first stage in plug-and-perf completions. The hydraulically activated sub is typically run as an economical backup option to the primary hydraulic toe sleeve. If required, the rupture discs will burst at a set pressure, to establish communication with the reservoir and enable wireline tools to be deployed to stimulate the first stage.

A CT run to perforate the first stage in plug-and-perf completions is eliminated with a hydraulically activated TREX Wet Shoe Sub. The sub is assembled just above the float collar. The landing dart that displaces cement is used to activate the sub and create a flowpath around the dart to establish communication with the reservoir and commence stimulation operations.

HYBRID COMPLETION SYSTEMS

Combining hydraulically activated toe subs with ball activated sliding sleeve technology in the lower stages of an

extended-reach lateral can further enhance the operational efficiency of the first stage. Ball-activated completions are often chosen for lower stages, because they do not require CT or wireline conveyance. Hybrid systems can provide flexibility in a variety of applications, including open hole or cemented liners, as well as single-point entry or limited-entry applications. Ball-activated sleeves in the toe of extended-reach laterals help start the treatment process faster and more efficiently than traditional plug-and-perf methods.

A crossover to change back to plug-and-perf or CT sleeves is typical at a measured depth, where upper stages are within easy reach. The hybrid combination is customizable to suit objectives and completion design requirements.

CASE STUDY: HYDRAULIC TOE SLEEVE

An operator working in the Permian basin installed the Toe-XT testable hydraulic sleeve to simplify operations for the first stage of a plug-and-perf well. The toe sleeve was successfully activated after nearly eight months downhole.

A casing integrity test to 8,900 psi was performed for 15 min. at 2 bpm before the sleeve was activated. The sleeve opened on the next pressure cycle, enabling stimulation of the first stage. The second stage of the well included five QuickPORT IV limited entry sliding sleeves to enable operations to continue without downtime between stages.

CASE STUDY: HYBRID COMPLETION

An operator working in the Permian basin successfully resolved operational issues in extended-reach laterals by deploying ball-activated sliding sleeves for the toe stages of its plug-and-perf completions.

One of the wells included 80 ball-activated, limited-entry sliding sleeves, segmented into 20 stages, to cover the deepest 3,900 ft of the lateral before reverting back to plug-and-perf for the rest of the well.

This hybrid completion technique proved effective, and all 20 stages were stimulated in less than 70 hr of pumping time. The ball-activated sliding sleeves provided a high stage count completion solution that reduced the intervention risk at the toe and saved the cost associated with downtime.

CONCLUSION

Hydraulically activated toe subs provide an effective and efficient method for initiating stimulation operations in extended-reach laterals. Deploying these tools at the toe of a well reduces operational risk associated with the conveyance of wireline or CT in extended-reach laterals. The subs enable effective stimulation of the toe stages, while minimizing NPT and expedite completion time to bring wells online faster. The hydraulic toe subs and ball-activated technologies provide cost- and time-effective solutions for the lower stages of an extended-reach lateral, whether the application is cemented, open-hole, limited, or single-point entry. WO

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Shale technology: Bayesian variable pressure decline-curve analysis for shale gas wells (March 2024)

- Using data to create new completion efficiencies (February 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- E&P outside the U.S. maintains a disciplined pace (February 2024)

- U.S. operators reduce activity as crude prices plunge (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)