OTC Spotlight on New Technology Awards: Innovation continues as offshore recovers

As the offshore sector of the global E&P industry shows signs of finally turning the corner, the strong pace of technical innovation is continuing. And it is technological advancements like the ones shown in this section that are helping to lower break-even costs dramatically for offshore projects. Each year, OTC recognizes innovative technologies with the Spotlight on New Technology Award. The program is exclusively for OTC exhibitors, and it showcases the latest and most advanced technologies that are leading the industry into the future. The 2019 Spotlight on New Technology winners are described on the next several pages. WO

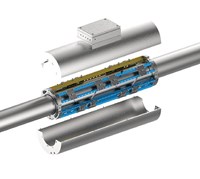

ACTIVE CONTROL DEVICE (ACD)

AFGlobal’s Active Control Device (ACD) improves the safety and performance of deepwater MPD by replacing conventional RCDs. It goes to the root of the problem with a non-rotating annular diverter. Its unique active pressure sealing system provides wellbore sealing, without bearings and rotating components to maintain.

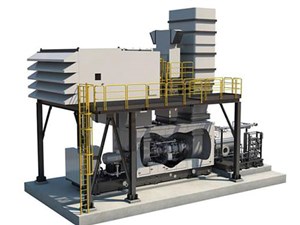

PUMP FOR CONTINUOUS DUTY HYDRAULIC FRACTURING

AFGlobal’s DuraStim pump technology is designed specifically for continuous duty hydraulic fracturing. It is a fully automated, electric long-stroke (48-in.) pump, featuring a low frequency (~20 cycles/min.) and it eliminates high-cycle rates that quickly destroy the fluid ends of conventional plunger pumps. For more details, please see the Technology at OTC section on page 35.

DOUBLE EXPANSION XPAK LINER HANGER

The TIW XPak Expandable Liner Hanger System from Dril-Quip is designed to run with standard liner applications and incorporates industry-proven expandable technology to provide a liner top anchor/sealing device unmatched in the industry. It can be used anywhere that a robust liner top seal is needed or where a slimhole design is required to mitigate ECD issues. Its design allows a relatively short expanded section to provide a pressure differential rating equal to the wellbore casing design and a hanging load capacity equal to, or greater than, conventional liner hangers. Its slim profile allows for rotation and/or drilling with liner operations.

TURBINE FOR PIPELINE COMPRESSION

BHGE’s NovaLT 16 is a turbine that improves plant performance through high fuel efficiency and low maintenance requirements. With a power turbine speed of 7,800 rpm, it is ideally suited for pipeline compression—with direct coupling to the latest PCL pipeline compressors, featuring high-performance stages and 89% or greater compressor efficiency. It is designed for a 35,000-hr mean time between maintenance, which translates to four years of non-stop running for the gas generator module or eight years for the power turbine module.

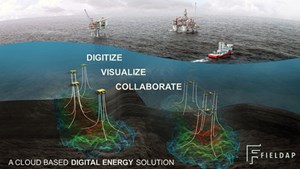

DIGITAL PLANNING PLATFORM

FutureOn’s Field Activity Planner (FieldAP) is a cloud-based digital platform that enables rapid visual workflows for offshore engineering work. It allows the easy integration with other backend systems and offshore engineering software already in use. With FieldAP, assets become smart. Smart assets store engineering, costing and configuration data. The platform enables a digital working environment for any organization and offers instant global collaboration.

ELECTRIC TORQUE TOOL

HYTORC’s LITHIUM SERIES Electric Torque Tool provides portability and convenience to any industrial bolting job. With the world’s first 36-volt industrial battery system, the tool is ready for heavy industrial use. The tool was designed from the ground up, using aerospace-grade materials to provide a compact design with industrial durability and power. Its metal frame is cut from a solid piece of aluminum alloy, which protects the tool from damage. Additionally, it features a simple switch allowing it to go from high-speed rundown mode to accurate final torque mode. This eliminates the need for multiple systems on the job. The precision machined gearbox provides constant power, without the vibration and noise found in impact guns. It makes torque and angle bolting simpler, as well.

SUBSEA PUMPING TECHNOLOGY

Operators can reduce or eliminate their topside footprint by moving chemical storage and injection capabilities subsea, via Oceaneering’s Subsea Pumping Technology (SPT). It offers alternate value-added contributions to subsea tie-back architectures and other operational applications, where chemicals or hydraulics are required for operational integrity management or flow insurance purposes. It supports the move toward unmanned or subsea factories, along with all-electric technologies being implemented in subsea architecture. SPT removes the need for complex umbilicals, allowing operators to engage in longer tiebacks with reduced capital expenditures.

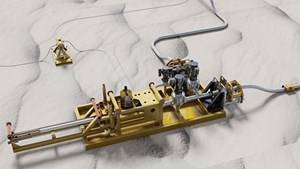

SUBSEA AUTOMATED PIG LAUNCHER

Operational pigging, without vessel or ROV support, is enabled by NOV’s Subsea Automated Pig Launcher (SAPL) solution. It is mounted on a subsea structure and loaded with pigs from a retrievable cassette. The cassette can house several pigs, which can be launched individually from shore or platform. The SAPL simplifies operations related to pre-commissioning and commissioning, wax control, slug control and intelligent pigging inspection.

VX OMNI SUBSEA MULTI-PHASE FLOWMETER

The Vx Omni subsea multiphase flowmeter from Schlumberger OneSubsea is a reduced-footprint, highly accurate flowmeter that takes application of flowmeter technology to 20,000 psi while expanding on capital efficiency, expediting lead times, and achieving a high degree of reliability. The number of parts in the Vx Omni flowmeter has been reduced by approximately 66%. More than 90% of these components, including the most advanced instrumentation, are standardized for pressure rating, process fluids compatibility, temperature, flowrate, and water depth. This flowmeter offers new possibilities for obtaining data about gas, oil, and water flow from subsea development wells, including those in remote locations. It can provide substantial cost-savings through downscaling or eliminating surface well testing facilities and subsea test lines.

CONCERT WELL TESTING LIVE PERFORMANCE

The Schlumberger Concert well testing live performance brings digital automation and communication to well testing by giving everyone the same real-time information and interactive capabilities. This seamless access and sharing of data, diagnostics and analysis improves efficiency, data quality, and safety to mitigate uncertainty and achieve actionable test results. A flexible wireless sensor network, wearable technology, and HD-cabled video cameras inform wellsite displays across ruggedized tablets and a web-based dashboard for customer screens—wherever one wants to see a well test. The concurrent analysis and advanced diagnostics refine the scope of work and predict operational events. Further improvements to test efficiency and HSE come from automated data acquisition that eliminates exposure to manual sampling and monitoring.

BLUEVAULT ENERGY STORAGE

BlueVault is Siemens’ lithium-ion battery-based energy storage solution that is suited for both all-electric and hybrid (i.e., diesel-electric) power applications. The solution is specifically designed to help ensure continuity of power and to minimize CO2 emissions, with an end goal of a low-emissions platform. The battery is designed to maximize life, performance and safety. BlueVault is being installed on Northern Drilling Ltd.'s West Mira offshore drilling rig that will operate in the North Sea's Nova field, approximately 120 km northwest of Bergen.

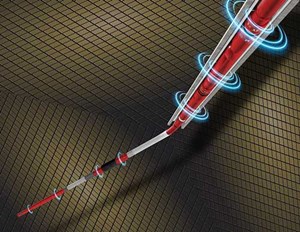

ULTRASONIC CLAMP-ON FLOWMETER

XSENS AS has, together with Christian Michelsen Research AS (CMR) in Norway, developed and patented disruptive ultrasonic flowmeter technology, providing helical signal transmission, enabling off-center measurement and the ability for almost tomographic pattern measurement. This provides accuracy similar to in-line multi-path flowmeters. The new clamp-on flowmeter simplifies installation, commissioning and maintenance compared to existing flowmeters, at comparable performance. Installed cost is significantly lower, and potential leakage and clogging points are eliminated. This is another OTC Small Business winner.

CONDITION-BASED MONITORING OF DRILLING RISER SYSTEMS

Stress Engineering has developed a new process for collecting critical riser data, which utilizes a life cycle condition-based monitoring (CBM), maintenance and inspection system. This system can be deployed on a mobile operating drilling unit (MODU). It enables resources to be deployed only when necessary, instead of on a calendar interval. The CBM system reliably determines the condition of drilling riser joints, consistently predicts when vital components will require service and accurately assesses remaining component life. The process has been certified by the American Bureau of Shipping (ABS).

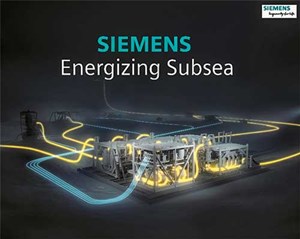

SUBSEA POWER GRID

Siemens’ Subsea Power Grid transforms field developments by extending tiebacks and allowing flexible subsea processing. It has subsea transformers, switchgear, variable speed drives, wet mate connectors, and a remote control and monitoring system and is ready to power large-scale subsea processing projects. The system is ideally suited to support enhanced recovery in subsea brownfield projects and tie-back fields, benefitting from single- or multi-phase boosting to increase oil recovery. In developing this new system, Siemens has collaborated with industry partners Chevron, Equinor, ExxonMobil and Eni Norge.

FIBER LIFTING CHAIN ELIMINATES WEIGHT OF STEEL

Green Pin Tycan is a high-performance fiber lifting chain that has the performance and flexibility of steel chain but is a fraction of the weight. It’s extremely safe and easy to use, non-corrosive and completely waterproof. By using Green Pin Tycan companies achieve greater efficiency and a safer working environment. This item is also one of OTC’s Small Business Award-winners.

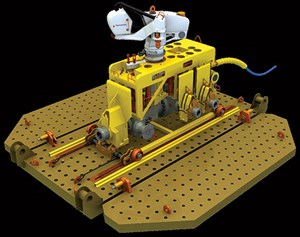

COMPACT MANIFOLD IMPROVES SUBSEA FIELD DEVELOPMENT ECONOMICS

The In-Line Compact Robotic Manifold from TechnipFMC is transforming the traditional manifold design to improve subsea economics. The compact manifold reduces size, weight and manufacturing cost and incorporates a robotic arm for valve actuation. For more information, please see the Technology at OTC section on page 40.

REMOTE-ACTIVATED, SINGLE-TRIP DEEPWATER COMPLETION SYSTEM

Weatherford International has brought to market what it calls the world's first remote-activated, single-trip deepwater completion system, known as TR1P. By combining the upper and lower completions in one trip, the system has been shown to reduce installation time between 40% and 60%, and to reduce rig time by four to six days. Using radio-frequency identification (RFID) technology, the field-proven TR1P system delivers 100% interventionless operation in both producer and injector wells. WO

Related Articles- Coiled tubing drilling’s role in the energy transition (March 2024)

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- The reserves replacement dilemma: Can intelligent digital technologies fill the supply gap? (March 2024)

- What's new in production (February 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Using data to create new completion efficiencies (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)