Digitizing operations increases completion efficiency, addresses environmental and cost challenges

To address ongoing challenges faced by the oil and gas industry, along with new client initiatives, TechnipFMC developed iComplete, a comprehensive completions technology ecosystem. From pump to wellhead, the fully integrated onshore completion system focuses on digitizing operations and addresses the environmental and cost challenges faced by the industry.

Integrating solutions for completions. Some may argue that unconventional completion technology has demonstrated some of the most notable advances in our industry during the last few years. From an operational standpoint, frac intensities continue to test the limit of equipment capabilities and overall reliability. From a product standpoint, there has been much progress in tackling technical challenges, such as increased treating pressure ratings; valve design that addresses sand ingress of various mesh sizes; large-bore single-line high-pressure delivery systems; and efficient wireline connectors, just to name a few. Individually, these products have helped drive today’s unconventional oil and gas renaissance. Through innovation, each pain point or portfolio gap in the operation has been addressed.

However, to ensure efficiency and prevent downtime, world class project management and logistics are required for execution. On site, hand-offs between operations, especially between operating entities, carry the risk of inefficiencies and human error. Individual standard operating procedures can be misinterpreted or be contradicting and require system-level understanding and direction. An integrated system approach, capable of digital operation and selective automation, is the preferred solution for safer operations, and down/idle time reduction. When designed and operated efficiently, this system integration may also carry a substantial reduction in emissions.

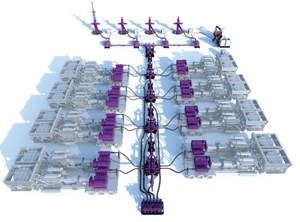

Integrated system hardware. Developing a standardized system that can address the majority of unconventional well sites requires a modular approach. Identifying key sub-systems and scoping down customer operational requirements to simplify the offering, well service pump-to-wellhead, was the first step in developing the iComplete ecosystem. Through internal benchmarks, this system has 50% less components and removes 80% of connections when compared to a typical site-built completions pad.

Less components and connections improve product reliability and reduce manpower needs on location, with the benefit of up to 50% faster rig-up. Major, standardized components are assembled and evaluated off-site, in a controlled shop environment. This results in improved equipment reliability and reduces the material movement, ultimately reducing logistics cost and greenhouse emissions in the process. The system comprises six major key subsystems: SAFlex, SuperFrac, Large-bore check valve, Frac trees/manifolds, Speedloc-XT and CyberFrac.

System delivers first oil faster, safer and smarter. The integrated system enables you to frac differently by leveraging flexible pipe, automation and digital efficiency to minimize complexity and eliminate intervention in the red zone. It offers more service capability, greater reliability and fewer emissions with the simplicity of one pad, one supplier and one invoice. The technology package minimizes complexities, so operators can focus on getting to first oil faster with 30% lower costs.

TECHOLOGY PLATFORM

The fully integrated system gets to first oil faster by leveraging flexible pipe, automation and advanced digital capabilities, to deliver greater efficiency with 80% fewer connections, Fig. 1. This means an elimination of human intervention in the red zone, making your frac pad faster, safer and smarter.

System integration. From pump to casing, we offer the simplicity of one pad, one supplier and one invoice. We leverage flexible pipe, automation and advanced digital capabilities to deliver operational efficiency, compatibility and ease of use. The system comes with 80% fewer connections and 50% fewer parts on the frac pad.

Next level HSE. The completion system eliminates red zone intervention, delivering a more secure work environment that significantly reduces the chance of human error. We make your frac pad safer, faster and smarter by enabling visual validation from a distance. Our simplified integrated system also promotes a healthier environment, reducing emissions through a 43% reduction in logistics.

Technology. The system leverages flexible pipe, automation and advanced digital technology to deliver greater operational efficiency. Increased uptime, lower NPT, remote operations, access to automation and real-time data logging are just a few of the benefits. Innovative technology delivers greater product performance with less maintenance, making frac pads smarter and lowering costs.

Digital automation. The system features digital automation services that will eliminate human intervention in the red zone. This makes the frac pad safer and more secure. Other benefits include data capture, remote operations and digital monitoring. The advanced digital capabilities promote positive predictability and minimize complexities to produce first oil up to 15 min. faster per frac stage.

The SAFlex product portfolio contains a de-marinized Coflexip high-pressure flexible, used in the same manner as traditional flow iron, Fig. 2. The products have been used successfully in harsh, fatigue cycle-prone, high-pressure offshore environments. Being designed and field-proven to withstand these conditions (with metocean data driven requirements in some of the harshest offshore locations in the world), they provide a natural solution to the high-pressure, high-cycle, modern frac pad requirements. Compared to traditional flow iron, SAFlex enables an 80% reduction of connections, substituting the articulation of rigid piping (and their independent connections) with a single connection on each end.

This drastically reduces make-up time and improves reliability by removing multiple potential leak paths. Reduction of leak paths inherently reduces fugitive emission situations. Finally, the flexible product dampens system vibrations, which help in dissipation of pump cavitation and reduction of erosion through piping, compared to traditional rigid flow iron. It is used to connect, both in pump to frac manifold missile and frac valve manifold to frac tree applications.

SuperFrac. One of the first single-line “missile” manifold systems to market, SuperFrac pods also follow a modular design to accomplish compatibility with various pad designs. Due to its standardized design, this system is configurable to various spacing constraints and number of frac pumps. It has a unique low-pressure flow design that also reduces pump cavitation and lowers pump maintenance. The high-pressure line utilizes robust API large-bore flanged connections with an industry standard metal-to-metal ring type joint capable of high flowrates and improved erosion resistance

Large-bore check valve. One of the premier large-bore check valves in the market, compared to traditional goat heads with flow iron, the large-bore check valve system reduces the number of connections from single-bore manifold to frac zipper, resulting in faster rig-up times and improved reliability with a reduction of leak paths, Fig. 3. Also, it is factory acceptance tested, with internal components inspected in a shop environment between jobs, it arrives at location configured to customer preferences. The system is expected to go through 500 stages without rebuild. But, if a rebuild is required, it has a top entry design that allows fast on-site repair and replacement of internal components. Its reliability and quick service design ensure on-pad operational efficiency and down-time reduction.

Frac trees and manifolds. At the heart of any frac operation, serving as pressure containment and control, frac trees and manifolds come in a variety of sizes, pressures and configurations. Individually, valve design has evolved incrementally, as frac intensities continue to increase. Compared to traditional production valves, frac valves have developed key design attributes that address valve reliability and lower on-site maintenance time and cost. For example, as sand mesh sizes continue to evolve, preventing sand ingress impacts seal-ability. This is addressed through valve seat design to ensure reliably clean sealing surfaces.

Compared to typical production valves, cavity volumes have been reduced to prevent sand accumulation and reduce grease quantity, the latter of which has a direct impact on carbon footprint as it pertains to hydrocarbon-based greases, and an indirect impact to emissions by reducing the amount of time required to grease a valve on location. Finally, logistics and installation are simplified with standardized tree and manifold configurations that are inspected, redressed and factory-tested in a shop environment. These tree and manifold sections arrive on location with minimal field testing and connection make-up requirements.

Speedloc-XT. Hydraulic connectors have long been used in subsea applications worldwide. They provide an efficient and reliable connection that can be performed remotely without human interface. Removing personnel from the red zone during connection make-up improves safety, especially through remote connection testing, keeping operators away from the pressure-containing envelope. The Speedloc-XT provides both a digital (through position indicators) and visual confirmation to ensure proper engagement prior to connection test and subsequent wireline and coil tubing operations, Fig. 4. Sensors in the connector prevent inadvertent valve operation, drastically reducing the instance of accidental wireline cuts.

Integration of sub systems. The aforementioned systems, individually, have direct operational impact by improving operator safety; increasing equipment reliability through standardization and shop built sub-systems; simplifying project logistics; and reducing operational costs through elimination of multiple connections that were once on-site built. Bringing these systems together, under one operating system that can relay real-time actionable wellsite data, further improves efficiencies in operations, can prevent downtime, and will improve HSE.

TechnipFMC’s CyberFrac suite achieves this by connecting these subsystems and providing the user interface to collect and action equipment status and performance in real time, Fig. 5. The system allows remote operation of its hardware with programmed operator standard procedures, through a “digital handshake.” Key personnel on site will have simultaneous awareness of upcoming operational steps and can abort mistaken commands reducing manual errors. These procedures are pre-programmed to avoid on-the-fly decision making.

For example, during wireline operations, sensors embedded in the Speedloc-XT acknowledge wireline presence and prevent operations that could lead to a catastrophic wireline cut. Valve closing operations must, instead, be manually overridden, thus preventing accidental wireline cutting, compared to a traditional HPU.

The complete CyberFrac package is comprised of the following:

- A master control station (MCS), using a proprietary UCOS Operating system that allows data analysis and remote operation of system hardware through hydraulic functions. This control station enforces standard operational procedures and provides safeguards that reduce accidental operations. Additional tablet controllers are paired to MCS and distributed to key operational personnel.

- A CyberHub, which is a system of hydraulic control valves, plumbed to a hydraulic power unit (HPU) that receives digital signals from the MCS to remotely actuate hydraulic functions, such as gate valve opening and closing, wireline connector lock/unlock and automated valve greasing, Fig. 6. CyberHub reduces HPU’s on location by providing distribution of multiple hydraulic functions through a single-valve control package.

- SAFSense wireless transmitters that provide digital signals, such as valve positions (open/close), pressure sensing, and equipment status.

- Automated greasing system that allows remote valve greasing for reduced NPT and cost reduction by avoiding over-greasing. Improvement to HSE also takes place by removing personnel from red zone to accomplish greasing operations.

CASE STUDIES

Although relatively new to market as an integrated system, iComplete’s early returns are encouraging. Below are recent success stories from an individual product standpoint. In the Eagle Ford, a pressure pumper using SAFlex and PumpFlex products achieved an 81% reduction in connections, with 100% elimination of hammer unions on treating iron. The customer also achieved a 50% reduction in rig-up time. Approximately 25 to 45 hr of NPT per month were saved by reducing leak paths. Pump swap times were also cut in half, utilizing PumpFlex lines compared to traditional flow iron.

TechnipFMC’s large-bore check valve achieved 2,500+ frac stages without a rebuild. At 100 bpm average, over one billion pounds (30/70 and 100 mesh) of sand were pumped during 1,500 hr of pump time at 12,500-psi treating pressure. This single 7 1/16-in., 15K large-bore valve replaced six 3-in. check valves, which also allowed the elimination of 346 hammer union connections, improving overall system reliability.

Integrated system performance. Although these individual examples provide component-level performance improvement, the integrated system has demonstrated that higher performance and efficiency ceilings are achievable.

A large independent achieved significant reduction of non-productive pump idle time, using CyberFrac. Overall, 34 hr of operational efficiency gains were achieved through digital handshake communication of key personnel outfitted with paired UCOS controls that maintained procedural compliance. This resulted in $245,000 in savings from these previously unknown transition delays. Over 3,100 pad operations were also achieved without red zone intervention.

Another operator saved $560,000 by completing a pad 2.5 days ahead of schedule. This was achieved by increasing average pump time efficiency on site from 17 hr/day to 22.5 hr/day. The largest improvement came from a reduction in transition time that was, on average, 49 min. per stage prior to using the digital handshake, to only 5 min. per stage afterward. Also on site, over 3,000 valve operations were performed outside of the red zone.

Automation and beyond. Our industry’s rich history of product innovation to tackle changes in requirements will continue to grow. Whether changes to industry standards, regulations, or wellbore demands, oil and gas products will continue to evolve to meet and exceed customer requirements. Individual product efficiency gains to lower cost, and improve performance, are key in meeting operational metrics that ensure the delivery of the world’s energy. However, an integrated package approach has shown an improvement in efficiency for on-site operations holistically, rather than the sum of individual products operated by individuals, with individual performance metrics.

By focusing on the integrated system performance, improvements in safety, quality and costs are achieved. More importantly, a dramatic reduction of emissions is demonstrated by simplifying and standardizing product architecture, reducing on site rig-up and idle time, streamlining operational steps and communication, and limiting material movement from shop to site. As we grow more comfortable with the integration of systems in a digital operational environment, more sequence of operations will become automated. It will be interesting to reflect back on today’s relatively new best practices as tomorrow’s standard operating procedure.

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Digital transformation/Late-life optimization: Harnessing data-driven strategies for late-life optimization (March 2024)

- Shale technology: Bayesian variable pressure decline-curve analysis for shale gas wells (March 2024)

- The reserves replacement dilemma: Can intelligent digital technologies fill the supply gap? (March 2024)

- Using data to create new completion efficiencies (February 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)