In an ideal world, operating companies would have a complete geological model—with full reservoir characterization—before beginning their horizontal drilling and hydraulic fracturing programs to develop unconventional resources. Unfortunately, companies seldom have time to get a complete picture before development must begin.

“In the U.S., a detailed seismic reservoir characterization is often used as a post-mortem analysis,” said Duane Dopkin, Executive V.P. – Geoscience at Paradigm.

COMPLEXITY

In addition to understanding conventional reservoir parameters, operators developing unconventionals also have to derive the unique properties of shale and other tight formations. These parameters include formation brittleness, total organic content (TOC), maturity, natural fracture patterns and the in-situ stress fields of the formation. Once assembled, this information enables operators to define the sweet spots.

However, because each unconventional basin has different characteristics, and there is a high degree of heterogeneity within each individual reservoir, operators must use flexible, creative workflows to gather information from all available sources.

“The process of imaging, characterizing, and interpreting shale plays is complex,” said Dopkin. “With conventional seismic data, we use seismic reflection data to establish a structural and stratigraphic framework, and to derive some basic reservoir properties. Both of these can contribute to the geometric and physical description of the reservoir. It’s not so simple with a shale resource play. We not only need to know the depth to the shale with a high degree of accuracy, but we also need to understand the structural and compositional fabric of the shale, and understand how it changes laterally and vertically.”

SEISMIC ACQUISITION

Recent advances in land seismic technology have enabled the acquisition of massive volumes of high-density, full-azimuth, single-sensor, surface seismic data, according to Charles Wagner, manager of Schlumberger’s Seismic for Unconventionals Center of Excellence.

“Historically, telemetry systems were unable to cope with ultra-high data rates,” Wagner said. “The response from several geophones was merged at recording time, irrevocably mixing receiver responses together. Today, each geophone can be recorded separately, with some systems recording as many as 100,000 live channels at each shot point.”

“With the onset of full azimuth land acquisition systems, the long-sought-after ability to analyze azimuthal variations in rock response—economically—has been realized. This is of critical importance to evaluation of unconventional resources, especially organic-rich shales,” Wagner said.

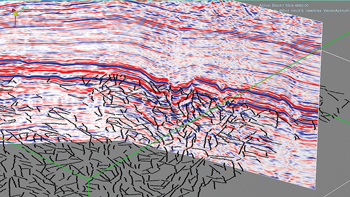

“The vertical resolution of surface seismic is such that faults and large fractures can be detected by identifying breaks in continuous seismic reflectors. But smaller fracture sets, which affect fluid flow and hydraulic fracture propagation, cannot be detected in such a way. However, using advanced seismic inversion methods and full azimuth high-density data, we can now quantitatively predict mechanical properties and natural fracture density in specific rock layers,” Wagner said.

SEISMIC PROCESSING FOR UNCONVENTIONALS

“The science of applying seismic data to shale plays puts tremendous pressure on geophysicists and the geophysical method,” said Dopkin. “For example, we have to use best practices to remove overburden effects.”

“If we are just interested in getting a good depth position to land the well and to geosteer through the formation, depth imaging, if properly applied, is strongly positioned to achieve this,” said Dopkin. “Today, we also want to understand the internal properties of the shale that will make us successful in terms of production. That is why the industry has developed tools to help achieve that understanding.”

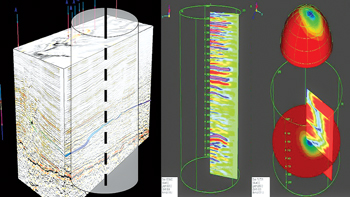

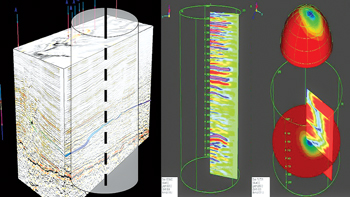

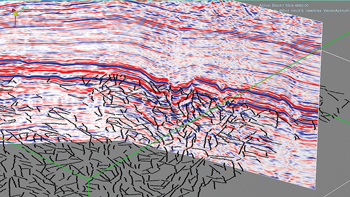

One such tool is Paradigm’s EarthStudy 360, Fig. 1. The system is designed to deliver data and information for consumption by geophysicists, geologists and drilling engineers. The program uses surface recorded seismic data to recover in-situ stresses and fractures that are difficult or impossible to recover with conventional seismic methods. Its ability to recover full azimuth data, in-situ, and in-depth allows geophysicists to create deliverables that can be correlated to well and engineering data.

|

| Fig. 1. Paradigm’s EarthStudy 360 provides rich information from all directions and reflection angles, resulting in high-quality imaging and velocity model building. |

|

“In general, the structural interpretation of the reservoir is much the same between conventional and unconventional reservoirs,” said Bill Ross, director, Geological and Geophysical Frameworks, at Landmark. “It’s well known that only one-third of frac stages meet expectations, one-third are marginal, and one-third contribute nothing to production. The big challenge is finding the sweet spot for the drill bit and the frac stages.”

“You also have to be aware of where you are in the basin,” Ross added. “In these petroleum systems, the shale is both the source rock and the reservoir. How deep is it? How long has it been down there? You need to fill in the layers to build your model, drill to your targets, and update your maps fast enough, so that they can improve performance on the next well.”

To facilitate this process, Landmark’s Decision Space Geosciences is a unified workspace bringing together geophysical, geological and petrophysical data.

Baker Hughes collaborates with CGG. Baker Hughes, in conjunction with CGG, is combining advanced, integrated, wellbore formation evaluation analysis with a variety of reservoir rock and fluid parameters from 3D seismic analysis to locate sweet spots across unconventional reservoirs, according to Amr El Hosary, product manager LWD seismic, Baker Hughes.

Near-wellbore anisotropy lithology, mineralogy, TOC, saturations, porosity, mechanical properties, fracture characterization and identification of stratigraphic sequences can be derived from log and seismic data and analysis.

CGG arrives at a variety of reservoir rock and fluid parameters from simultaneous inversion processing of the 3D seismic. Then, using Hampson-Russell software, CGG models multi-attribute lithofacies, volumetrics and other key determinants (including TOC). These results are calibrated with wellbore data to extrapolate these characteristics across the reservoir for sweet spot identification.

GEOMECHANICS

Because the success of fracturing programs depends on the in-situ stresses and brittleness of unconventional reservoirs, geomechanics has become extremely important in reservoir characterization. A recent paper described a field-scale study of the geomechanics of the Haynesville shale,1 which systematically identified shale layers in the field, where wells were most likely to be productive.

The study identified one class of rock as the most promising for production. This rock class has uniformity in mechanical properties, rock fabric and in-situ stress, except for regions with structural changes and curvature. The study’s model also showed that these shale layers would result in high-producing wells, only if they were contained by stronger rock class layers located above them. The analysis was confirmed by the fact that more than 75% of the best producing wells in this region of the play are in reservoir layers beneath the containing rock class.

RESERVOIR FLUID CHARACTERISTICS

A recent paper by Exxon Mobil concluded that the performance of liquids-rich reservoirs is dependent on in-place fluid composition and phase behavior. The study presented an overview of fluid types in tight reservoirs, from black oil to dry gas, and described their impact on key reservoir characteristics, based on the extent of organic matter development and the physics of the related fluid production.

The study found that, unlike conventional liquids reservoirs, the most promising unconventional resources have gas-dominated transport mechanisms, so understanding the phase behavior of liquids, and its impact on well performance, is a critically important economic consideration.

Because unconventional reservoirs have extremely low permeability, high drawdowns are required for production, so it is difficult to obtain single-phase fluid samples. Representative, initial fluid samples are needed to accurately forecast future performance, but obtaining these is, currently, impractical for some rich-liquid systems.

Core and fluid sampling. Halliburton has addressed this need by developing a system that captures core samples, at reservoir pressure, and seals them downhole. The company’s wireline-deployed CoreVault system takes large-diameter cores and recovers 100% of the fluid contained in the core sample, Fig. 2.

|

| Fig. 2. Halliburton’s CoreVault system takes large-diameter cores and recovers 100% of the fluid contained in the core sample. |

|

WIRELINE AND LWD LOGGING

Wireline logging also faces challenges in unconventional reservoirs. “Shale and other tight reservoirs require a more targeted suite of measurements than conventional reservoirs,” said John Dahl, product line manager, Petrophysics, at Baker Hughes. “After the initial pilot well logs, data acquisition becomes more challenging in long horizontal wells.

“Also, Archie’s equation (for water saturation) doesn’t apply in shale reservoirs, so you can’t use conventional methods to calculate barrels in place. Production is driven by stimulation effectiveness, so you are more interested in understanding mineralogy, geomechanics and total organic carbon,” Dahl said.

Log data—taken by either conveyance method—can be difficult to interpret, according to Martina Nardi, Global LWD Formation Evaluation manager at Weatherford. “Log responses—especially from gamma ray—can differ significantly in shale reservoirs, due to their organic content,” Nardi said.

“In conventional reservoirs, the gamma ray is a lithology indicator that distinguishes between shale (high gamma ray) and sand (low gamma ray). In shale plays, the organic content is often associated with high uranium values and, therefore, the typical sand/shale evaluation is no longer valid.

“In addition to standard triple combo measurements (gamma, ray, resistivity, density and neutron), a spectral gamma ray that resolves the gamma ray counts into the elements of uranium, thorium and potassium can help determine shale brittleness and calculate the TOC. The data can also be used to identify the types of clay in the shales. This significantly affects the fracability of the rock,” Nardi said.

Petrophysical interpretation for unconventional reservoirs needs a different approach than conventional log interpretation, said Camilo Mejia, U.S. Regional LWD Formation Evaluation supervisor at Weatherford. “Understanding the geomechanical properties of shale, which control the occurrence of natural fractures and the creation of hydraulically induced fractures, is key to successful stimulation and completion of wells in a shale reservoir,” Mejia said.

“Weatherford developed the CrossWave LWD sonic tool that provides 360° azimuthally focused measurements of compressional- and shear-wave velocities, enabling 3D characterization of geomechanical properties along the length of the horizontal wellbore in mechanically anisotropic shale reservoirs,” added Mejia. Using data provided by this service, the operator can select the best areas for stage placement, while optimizing the fracture-treatment design and execution.

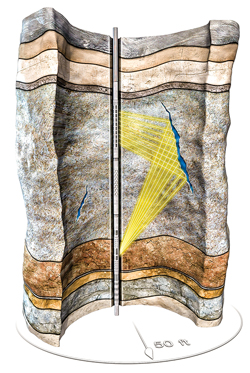

LWD imaging in the Barnett. As infield drilling has increased in the Barnett shale, collision and encroachment from well to well has become a growing concern, Fig. 3. Encana teamed up with Baker Hughes to demonstrate the use of high-resolution images to optimize perforation spacing, and to redesign stimulation and stage placement.2 High-resolution, state-of-the-art LWD imaging tools were used to acquire images on a well drilled between two 600-ft (182.9 m) offset wells.

|

| Fig. 3. Collision and encroachment from well to well has become a growing concern, as infield drilling has increased in the Barnett shale of Texas. |

|

Baker Hughes’ StarTrak high-definition LWD imaging service records micro-resistivity measurements around the circumference of the borehole, with the BHA’s rotation, with azimuthal measurements acquired in 120 separate oriented sectors. The resolution of StarTrak LWD imaging is based on the electrode diameter of 0.22 in., providing the industry’s highest resolution LWD imaging service. As the BHA rotates, the sensor rotates, as well, and scans the near-wellbore formation. The sensor records microresistivity measurement along the circumference of the wellbore, and a high-resolution magnetometer is used to reference the image to magnetic north.

The images from Encana’s well were used to map fracture systems, faults and stresses in the field. With the knowledge obtained from these LWD images, completions have been redesigned to optimize fracture treatments, enabling increases in well productivity of up to 20%, compared to offset wells.

DEEP SHEAR WAVE IMAGING

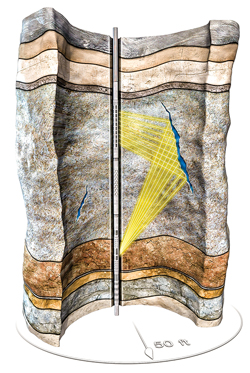

In extremely low-permeability formations, gaining insight into the natural fracture system, both intersecting and around the borehole, is crucial. Baker Hughes’ FracXplorer deep shear wave imaging system promises to improve detection of subseismic faults up to 60 ft from the borehole.

Standard methods of fracture evaluation can only investigate a limited area around the borehole. Imaging looks at the borehole wall, while the other borehole acoustic methods rely on refracted and guided modes that extend only 2 ft to 4 ft into the formation. The flexural wave from the dipole source is one of the guided modes that, generally, reads the deepest into the formation and is used in the standard cross-dipole analysis.

The dipole source flexural waves travel near shear wave velocity at low frequency. When these waves move away from the borehole and impinge on a fracture, their energy reflects back to the receivers in the borehole, enabling the fracture to be imaged. The strongest response occurs from the shear waves intersecting a fluid/gas filled fracture and polarizing in the fracture’s strike direction. The shear waves also have azimuthal sensitivity, so fracture direction can be determined. These features enable evaluation of fractures up to 60 ft from the borehole, even detecting major events that do not intersect the well. The system also can image geologic features that cannot be detected by the surface seismic, such as the occurrence of sub-seismic faults. Baker Hughes ran field trials of the new FracXplorer service to compare shear wave analysis with cross-dipole acoustic logs in three shale basins and a tight sandstone formation, Fig. 4.3

|

| Fig. 4. Baker Hughes’ FracXplorer deep shear, wave imaging system facilitates detection of subseismic faults. |

|

NUCLEAR MAGNETIC RESONANCE

Nuclear Magnetic Resonance (NMR) logs are useful in determining the effective permeability of unconventional formations, down to the nanodarcy range. NMR logs can provide a better picture than density, neutron and resistivity measurements.

“NMR gives a clear estimate of total porosity and an effective means of validating our petrophysical interpretation,” said Dan Buller, principal petrophysicist at Halliburton. The company discussed the use of NMR technology in unconventional formations, in a paper delivered at a recent conference.4 Density and neutron measurements don’t always respond to these subtle alterations and changes within the rock. In addition, porosity measurements provide no indication of permeability.

However, because NMR measurements directly measure the rock’s pore size, they can detect variations in porosity and permeability within the formation. The direct measurement of effective porosity provides a fairly accurate evaluation of reservoir storage capacity. The pore size measurement, achieved by the relaxation measurement of the NMR device, enables the calculation of relative permeability, matching the permeability measured in cores in the lab.

INTEGRATED WIRELINE EVALUATION

In a recent paper,5 Saudi Aramco presented the results of combining wireline, NMR geomechanical and dielectric data to evaluate reservoirs in Texas’ Eagle Ford shale and Saudi Arabia’s Qusaiba shale. The authors discussed how large variations in the mineralogy resulted in significant variation in the grain density. Saudi Aramco found that wireline geochemical logs effectively predicted an accurate grain density, even when there were large variations in mineralogy and TOC. Dielectric measurements were used as an alternative to micro-resistivity logs, which can be inaccurate in formations containing kerogen, to derive water saturation values.

NMR measurements were also incorporated into shale reservoir interpretations. When the NMR porosities were overlaid in shale reservoir zones devoid of kerogen, the density porosity measurement was a good prediction of the kerogen volume. In addition, the difference between the NMR porosity and dielectric apparent water-filled porosity was lower bound on the volume of hydrocarbon in both shale fields studied.

ADVANCES IN SURFACE LOGGING

Because of the difficulty in obtaining and interpreting wireline logs in unconventional shale formations, companies have turned to surface logging and geochemical analysis. “Unconventional shale operators need much more information about the formations than traditional mud logging analysis can deliver,” said Neil Cardy, Advanced Cuttings Evaluation product manager at Baker Hughes. “They need to know what clay minerals are included in the shale, the TOC, and the amount of dolomite and other rock types that could affect reserves calculations.”

Until recently, answering these questions has required laboratory analysis, which was usually done after the well was completed. Baker Hughes’ Advanced Cuttings Evaluation (ACE) service uses a range of analytical methods to contribute to a full understanding of the reservoir while drilling. The service uses a high-resolution digital (HRD) microscope to create images of sedimentological features; mineral assemblages and cements; and grain morphologies. Digital imagery from cutting samples can be transmitted in real time, making it easier to discuss formation lithologies with the operator’s asset team.

Another advanced component, the X-ray fluorescence (XRF) service, can identify elements by measuring the emission of characteristic "secondary" or fluorescent X-rays from a sample that has been excited by bombardment with high-energy X-rays. X-ray diffraction (XRD) analysis measures the scattering of a beam of X-rays when passed through a crystalline material. This analysis identifies the minerals present in the sample, including clay minerals.

Rig site pyrolysis analysis identifies the amount, type and maturity of the kerogen in the formation. This enables real-time identification of productive and non-productive zones. Previously, this analysis had to be performed at a laboratory.

“By combining advanced cuttings evaluation in the vertical wells with LWD and wireline logs, including elemental tools, the cuttings can then be analyzed in the horizontal sections to characterize the laterals,” Cardy explained. “This can enable the well to be geosteered, so that the well path stays in the sweet spot.”

Baker Hughes and CGG have combined their portfolios to bring CGG Robertson RoqSCAN wellsite mineralogical analysis to the rig site. This technology uses a portable scanning electron microscope (SEM) fitted with X-ray detectors to give an automatic quantitative and diagnostic analysis of mineralogy and texture (including porosity) within 30 min. of the sample arriving at surface.

MICROSEISMIC MONITORING

There have been a number of studies6, 7 using microseismic techniques to quantify stimulated rock volume produced during fractured completions, to measure hydraulic fracture half-lengths during fracturing, and to map the geomechanics of shale reservoirs. In addition to being central to extensive engineering projects, microseismic technology has become a commercial service in most unconventional plays. For example, Pinnacle, a Halliburton service, is working with operators in the Eagle Ford, Marcellus, Wolfcamp and other unconventional plays to help evaluate hydraulic fracturing on a practical basis.

“The trend in fracturing is toward tighter perforating clusters and smaller spacing for wells,” said Charlie Waltman, Microseismic product champion at Pinnacle. “Operators are using microseismic during fracing to determine how close to space the wells, and to decide whether to stagger them in TVD or stack them.” Microseismic monitoring helps determine whether the lateral is placed at the right depth by measuring the height of the frac and determining if there is any out-of-zone growth.

Pinnacle recently introduced a new service in fracture diagnostics. FracHeight service involves a new hybrid tool, deployed in an offset monitor well, that combines fiber optic wireline-conveyed microseismic receivers with Pinnacle’s downhole tiltmeter sensors that directly measure the formation movement associated with fracture dilation.

INTEGRATING RESERVOIR DATA

With a wide range of technologies for reservoir characterization, it is easy for operating companies to be overwhelmed with data and potentially overlapping services. The whole process can be optimized, using software tools that combine data and models to facilitate collaboration as a project is being implemented.

A recent paper by BHP Billiton8 described a workflow process that the company has used to develop assets in the Eagle Ford. Recognizing the uncertainties that exist in reservoir and completion parameters, BHP Billiton used a history-matching process to optimize drilling, well spacing and landing points for laterals, as well as stage lengths and completion and hydraulic fracturing design.

REFERENCES

- Rodriguez-Herrera, A.E., et al, “Field scale geomechanical characterization of Haynesville shale,” ARMA paper 13-678, 47th U.S. Rock Mechanics/Geomechanics Symposium, San Francisco, Calif., June 2-26, 2013.

- Janwadkar, S., “High-resolution LWD images used to optimize completions in unconventional play—North America resistivity imaging,” SPE/EAGE paper 152303, European Unconventional Resources Conference and Exhibition, Vienna, Austria, March 20-22, 2012.

- Patterson, D., et al, “Unconventional reservoir fracture evaluation utilizing deep shear-wave imaging,” IPTC paper 16958, International Petroleum Technology Conference, Beijing, China, March 26-28, 2013.

- Smith, C., “Magnetic resonance to identify permeability in shale reservoirs,” SPE paper 166992, SPE Unconventional Resources Conference and Exhibition–Asia Pacific, Brisbane, Australia, Nov. 11-13, 2013.

- Musharfi, N., et al, “Combining wireline, geochemical, NMR and dielectric data for formation evaluation and reservoir characterization,” SPWLA paper D 11 00074, 53rd Annual Logging Symposium, Cartagena, Colombia, June 16-20, 2012.

- Gongopadhyay, A., et al, “Understanding unconventionals by multidisciplinary integration – A microseismic based tale of the Haynesville shale,” SPE paper 164531, Unconventional Resources Conference–U.S., The Woodlands, Texas, April 10-12, 2013.

- “Geologic methods for evaluation in a brave new world–Unconventional reservoir monitoring,” SPE paper 168717, Unconventional Resource Technology Conference, Denver, Colo., Aug. 12-14, 2013.

- Cook, D., et al, “Unconventional asset development workflow for Eagle Ford shale,” SPE paper 168973, SPE Unconventional Resources Conference–U.S., The Woodlands, Texas, April 1-3, 2014.

|