Advanced LIMS: A crucial technology in the future of the oil and gas industry

The oil and gas industry must constantly evolve in response to internal and external pressures, such as ever-more-stringent environmental regulations. To stay competitive, organizations are required to continuously enhance their productivity, efficiency and sustainability, whilst upholding the quality of products for their customers. New technologies to support companies in their endeavors are, therefore, critical.

Digital transformation—the integration of digital technologies across a business—is emerging as a comprehensive solution to help companies boost productivity and quality. When correctly implemented, digital transformation in the lab offers a range of advantages, including increased connectivity to improve operational speed and efficiency. By eliminating manual processes, digital transformation also reduces the chances of error, thereby enhancing the accuracy and reliability of lab results. Additionally, digital solutions offer advanced security features to protect sensitive data from breaches and leaks, and can be designed to align with various regulations to simplify regulatory and environmental compliance.

A critical component in the digital transformation journey is an advanced laboratory information management system (LIMS).

This article explores how digital transformation, and particularly a LIMS, can help the industry solve complex problems, leading to increased productivity and new opportunities for process enhancements.

An industry riddled with challenges and complexities. In the upstream oil and gas sector, organizations require efficient ways of determining the viability of a source before beginning extraction, as this critical element often spells the difference between profitability and financial losses. Laboratories play a pivotal role during exploration, determining where best to invest resources to maximize returns from extraction. To do so, labs must secure vital information about the quality of a material, its composition, and the viability of the extraction site.

Processes upstream, therefore, generate a multitude of samples, each associated with a wealth of data. But workflows are already highly complex, without the pressure of increased throughput:

- Samples need efficient management, interpretation and reporting, which can put a significant strain on personnel, who record data manually, particularly as the demand for more elaborate data reporting is on the rise.

- Labs must uphold data integrity, but manual transcription introduces the risk of errors.

- Organizations require an efficient system for environmental impact assessments and mitigations, as the industry faces more stringent guidelines for exploration projects.

- Labs have to expedite sample turnaround times, in the wake of heightened competition and demand.

- Personnel need to access real-time data, which is not feasible or traceable when it exists across multiple disconnected systems.

- Labs must comply with:

- ISO 17025, which mandates full sample traceability, instrument calibration and maintenance, employee training on SOPs, and inventory control.

- American Society for Testing and Materials (ASTM) D6299, a standard practice for quality assurance and statistical quality control charting.

- Data should be sharable, both internally and externally. In particular, upstream labs must provide composition data in a streamlined manner to allow refineries to efficiently prepare for deliveries.

A much-needed digital transformation for the industry. Digital transformation offers a promising solution to the challenges in the oil and gas industry detailed above. There are five key benefits of digitally transforming an organization:

- Improved sample management: Labs can manage samples more efficiently, accurately tracking and logging all associated data while simplifying the overall procedure.

- Highly accessible data: Digitalization enables lab data centralization and standardization, making data searchable, transferrable and secure.

- Increased reliability: Labs can define standard operating procedures (SOPs), ensuring that experimental results are reproducible, irrespective of the analyst conducting the experiment.

- Enhanced decision-making capabilities: Personnel have the information and insights they need to make informed decisions.

- Greater sustainability: Digitalization eliminates remaining paper-based processes, labs can better manage their consumables to reduce waste, and it simplifies compliance to environmental regulations.

When embarking on a digital transformation journey, labs must undertake several critical steps. Firstly, it is important to connect as many elements as possible, from processes and instruments to consumables, systems, and people. Connectivity is crucial, as it lays the groundwork for streamlining operations. Labs can then automate end-to-end workflows, greatly reducing manual intervention and the associated risk of errors, while also improving operational efficiency. Finally, implementing advanced analytics leveraging technologies like artificial intelligence (AI) and machine learning (ML) can provide deeper insights and predictive capabilities, further improving decision-making and operational efficiency.

An advanced LIMS is the key tool that enables the steps mentioned above, paving the way for increased productivity, reliability and compliance. By centralizing data and automating processes, a LIMS provides a solid foundation for the wider digital transformation of oil and gas labs, leading to greater efficiencies and improved regulatory compliance. So, how does a LIMS facilitate digital transformation?

LIMS: A productive, reliable and compliant solution. A LIMS is a comprehensive solution designed to enhance data collection, management and analysis across all workflows within the oil and gas industry, including both exploration/geologic sampling and quality control. While some labs may opt for a separate LIMS for exploration and quality control, this can place a high demand on internal IT systems, thereby potentially hindering digital transformation.

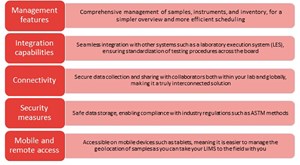

In contrast, an all-in-one flexible LIMS can manage all samples within a single system, which eases the burden on IT infrastructure and simplifies the internal IT and data landscape. The key features of an all-in-one LIMS for the industry are in Fig. 1. By leveraging such features, a LIMS offers a multitude of benefits to the industry, including:

- Improved management: Organizations can track and control all parts of their operations from sample management to instrument calibration and maintenance, Fig. 2.

- Greater productivity: Personnel spend much less time managing data, as the LIMS does it for them—so they can focus on higher value tasks.

- More reliable data: A LIMS eliminates transcription errors, as it moves data automatically, and stores a record in an audit trail.

- Higher throughput: Labs are well-equipped to cope with increasing sample volumes, as a LIMS can connect and support automation across different streams of the supply chain.

- Simpler compliance: The LIMS systematically collects all data and metadata, allowing labs to easily demonstrate adherence to regulations such as ISO 17025 and ASTM D6299.

But the benefits don’t stop there. A LIMS can also ready data to bolster productivity with more advanced solutions such as digital twinning.

Digital twinning is the future of the industry. A digital twin is a virtual representation of a physical entity constructed using real-time data obtained from various systems. Thanks to advancements, such as 5G communication and sophisticated software solutions like LIMS, digital twins have become increasingly viable and are already employed across a diverse range of sectors, from the food and beverage industry to aerospace. In the near future, it is likely that all companies will embrace digital twins as part of their operational ecosystem to maximize their productivity.

What can digital twins do? In the oil and gas industry, digital twins can be employed for numerous purposes:

- Enabling remote viewing of different extraction sites, allowing personnel to understand where the resource is located and the volume of the resource available.

- Training personnel on the oil plant system, providing a safe and controlled environment for learning.

- Supporting labs in running simulations within the extraction phase, offering insights into which parts of a system are most likely to fail first or suggesting ways to reduce the consumption of consumables.

- Helping users adjust the frequencies of maintenance schedules for instruments or testing schedules in a continuous manufacturing process.

Digital twins offer multiple benefits, regardless of the specific application. They can enhance the skills and knowledge of personnel, enable more informed decision-making and extraction processes (for example, helping to avoid oil spills), and enable full traceability in processes, which is crucial for regulatory compliance and process optimization. And ultimately, by optimizing procedures, digital twins can support oil and gas labs in improving the sustainability of their processes.

LIMS is the backbone of digital twinning. It is crucial to note that a digital twin's accuracy is directly proportional to the quality of the data that creates it. Therefore, a LIMS, known for its expertise in safeguarding data and metadata from a multitude of sources and applications, is central to creating an effective digital twin. By providing these data, a LIMS can enable labs to simulate changes to a process and predict potential impacts, providing critical foresight for decision-making.

A LIMS readies data for further analysis and for constructing representative models. But it can seem daunting to know where to begin setting up a digital twin. Luckily, the LIMS supplier can play a vital role by assisting in building a digital twin for organizations. Labs should, therefore, seek a LIMS supplier that provides the highest level of customer service, and will continue to work with them even after the initial LIMS implementation.

Digitally transform workflows for greater productivity. Digital transformation is vital to help organizations stay competitive within the rapidly evolving oil and gas industry, and ensure they continue to deliver high-quality, efficient services. A LIMS is at the heart of this transformation, propelling companies towards a future of increased productivity, reduced errors, and simplified compliance. Integrating all data within a single solution facilitates effective management, offers seamless connectivity, provides robust security, and guarantees easy access to critical information even in the field. Furthermore, LIMS introduces the potential for creating digital twins, enabling unprecedented levels of analysis, prediction and process optimization.

But the value of a LIMS extends beyond the confines of the laboratory or the extraction site. Through the digital transformation journey, organizations can improve their sustainability practices, to ensure safer processes for a healthier world—all while maintaining their competitive edge.