Nissan Chemical's nanoActiv EFT increases initial oil and gas production

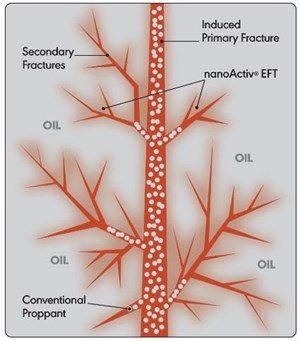

Pasadena, Texas -- Nissan Chemical America Corporation (NCA) introduces enhanced flowback technology (EFT) to complement its existing line of nanoActiv products. nanoActiv EFT is a nanoparticle micellar dispersion, employing a synergistic combination of a soybean extract solvent, a blend of surfactants and, NCA’s proprietary, patent-pending surface-modified silicon dioxide nanoparticles.

“One of the big challenges with hydraulic fracturing is that fracturing fluid filtrate can get trapped into the pore spaces in unconventional reservoirs causing a decrease in hydrocarbon mobility,” explains NCA President, William L. Smith.

nanoActiv EFT improves stimulation fluid interaction near the created and propped fracture faces and throughout the entire propped fracture network — increasing initial oil and gas production. It also delivers the unique advantages of fragmentation and reduction in interfacial tension.

“The presence of Nissan Chemical’s supercharged nanoparticles in nanoActiv EFT significantly increases the efficiency of the technology by contacting more surface area with a Brownian-motion, diffusion-driven mechanism known as disjoining pressure,” says NCA senior petroleum engineer, Yusra Ahmad.

Nissan Chemical's nanoActiv EFT joins the existing nanoActiv® product line to deliver significantly more efficient and complete flowback of the fracturing fluids in a shorter period of time. nanoActiv products demonstrate Nissan Chemical's commitment to supplying productive and innovative treatment fluids to the oil and gas industry.

“nanoActiv” is a Registered Trademark of Nissan Chemical America Corporation.