Chemstream proves ShaleTech advances start in the lab

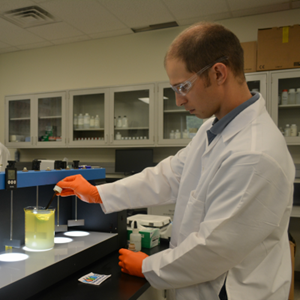

HOMER CITY, Pa. -- In the past year, Chemstream has transformed what once was a small area nestled at one end of the company’s headquarters into a spacious, state-of-the-art laboratory.

“We built an oilfield division as an extension to Chemstream, which once was known primarily for its work in the coal industry, water treatment and dust suppression solutions,” said Dave Grottenthaler, who heads Chemstream’s Oilfield Services. “The lab is the cornerstone. There is science behind all the decisions that impact the work we do in the field,” added Grottenthaler, who has extensive experience in most of the United States shale plays and realized that each shale requires a combination of proper strategies to unlock the reservoir’s full potential. “We let your formation geology and frac water quality determine the proper frac fluid design.”

Cutting-edge technology such as a customized friction flow loop, rotational viscometer, gas chromatography-mass spectrometry (GC-MS) with pyrolysis, and X-ray diffraction (XRD) has enabled Chemstream to make significant inroads into the oil and gas industry.

“We perform cuttings analysis to determine the mineralogy and the constituents that are present,” Grottenthaler said. “We evaluate and use the client’s water sources to tailor the appropriate chemistries specific to their needs.”

Chemstream spent approximately a year enhancing its in-house laboratory and technical staff to perform treatability studies on samples through use of analytical techniques. These studies enable Chemstream to determine which products provide the right solution in the most costeffective manner while offering quality control and quality assurance standards.

“The lab is the complete package,” said Brandon LaBrozzi, Chemstream Director of Operations and Engineering. “All of the equipment and technology complements one another in some form or fashion. We are capable of vetting different friction reducers and confirm compatibilities with the other frac fluid components. It isn’t necessarily one piece of equipment making the difference, it is all of the equipment and technology together.”

That technology has helped Chemstream make a significant impact in oilfield services.

“We are able to help our clients reach an informed decision,” LaBrozzi said. “Where others might simply recommend what has worked in the past, we realize that the same process might not work this time. We look at the water quality and shale constituents and put it all together. We tell the client, ‘Yeah, it’s going to work,’ or ‘No, it’s not going to work.’”

The combination of optimal lab equipment provides Chemstream the capability to “analyze stimulations and chemical packages,” LaBrozzi said. “We can make sure chemicals interact in a positive way so that the client can be confident ahead of the frac that everything is going to go well.”

The lab is utilized to perform post-frac sequential flowback studies to confirm the efficacy of the scale control and microbiocides used during stimulations. Water quality trend analyses allow for a better understanding of chemical performance, and any possible changes needed for future exploration in nearby locations.

This same lab support is capable of analyzing and confirming proper chemical recommendation for the frac plug drill-out, the well production chemical needs, and ultimately the proper water treatment ahead of disposal to an injection well.

In only a year’s time, the modern laboratory has helped Chemstream establish a strong presence in the oilfield services industry. And, as the lab continues to evolve with new and better technology, better products will be developed to heighten industry standards.