Case study: Innovative remote simul-frac creates efficiency and cost savings for Permian operator

Challenge:

An operator working in the Delaware Basin wanted to increase efficiencies by simul-fracing two, three-well pads that were about 1,200 ft apart. Traditionally, all simul-fracs completed for this operator included a minimum of four wells on one pad and were completed in a 2-by-2 well format to obtain the full benefits of simul-frac operations. Connecting two, three-well pads added additional technical challenges.

Solution:

Through collaboration with Universal, the operator executed a remote simul-frac operation to complete the two, three-well pads at the same time. A remote simul-frac is a method to frac multiple pads from a centralized location. The frac equipment was rigged up on one of the two pads (Pad A) connected to the other pad (Pad B) with roughly 1,600 ft of 7-in. spool iron. A set of pumpdown equipment, wireline unit, and crane were needed on pad B along with additional communication between the pads to maintain safe operations.

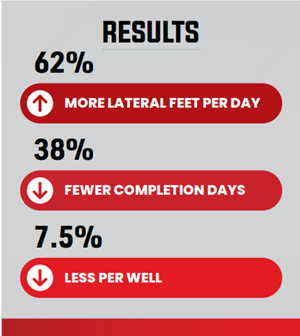

Results:

With the ability to complete all six wells simultaneously, the operator improved lateral feet completed per day by roughly 62% and cut completion time by 38% compared to completing two, three-well zipper pads individually. Increasing efficiencies led to a cost reduction of around 7.5% per well. A remote operation allows the operator to simul-frac non-traditional pads without changing the frac design.

Past performance does not guarantee future results. Results may vary.