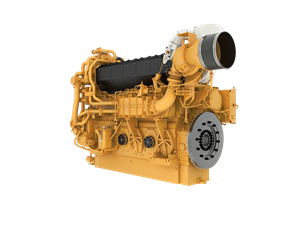

Caterpillar Oil & Gas introduces new gas compressing engine for lower operator emissions

(WO) – Caterpillar Oil & Gas introduced the new Cat® G3600 Gen 2 Engine, the latest evolution of the powerful G3600 series. With more than 8,500 Cat G3600 units in the field, the Cat G3600 Gen 2 engine is designed to build upon the robust platform’s performance to provide a 10% increase in power and lower emissions compared to the previous model. The Cat G3600 Gen 2’s design has the potential to reduce the number of engines required on-site to reduce capital and operating expenses as well as fuel consumption, enabling today’s gas compression operators to move more gas at a lower cost.

Running at full load, the Cat G3600 Gen 2 provides 33% lower methane on g/bhp basis and 6% greenhouse gas (GHG) reduction while achieving a 9.6% higher flow rate as compared to the previous model. Its ability to operate at lower exhaust gas temperatures affords operators a wider fuel quality tolerance, greater longevity, increased higher brake-specific fuel efficiency and reduced detonation.

Additionally, the Cat G3600 Gen 2 engine has demonstrated improved durability in the field and is designed for up to 100,000 hours of operation before requiring a rebuild, with recommended maintenance. Reliable aftermarket support and parts availability combined with the engine’s long life reduces operators’ total cost of ownership (TCO).

“With the Cat G3600 Gen 2, midstream gas compression companies can move more gas with fewer engines,” stated Matt O’Sullivan Caterpillar Oil & Gas General Manager. “Companies are enabled to achieve their operational priorities while maintaining performance and efficiency.”