Introducing riserless light well intervention stack, systems to monitor subsea production

At OTC 2015, FMC Technologies will showcase its latest light well intervention stack and both hardware and software systems to help operators monitor their field operations in real time and ensure the integrity of subsea production systems.

RISERLESS LIGHT WELL INTERVENTION

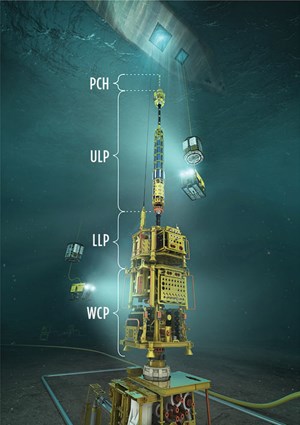

FMC Technologies’ third-generation, riser-less, light well intervention (RLWI) stack is designed for well control operations to a 6,500-ft water depth, Fig. 1. The RLWI Stack #4 has been installed on the subsea support vessel, Island Performer, chartered by FTO Services, a joint venture between FMC Technologies and Edison Chouest Offshore, Fig. 2.

Three previous RLWI stacks were built to work in the North Sea, down to a water depth of 3,300 ft. The first stack began operating in 2005 and results were so successful that two additional stacks were added in 2009.

The RLWI stack allows control of subsea trees from the RLWI vessel. The stack has a lubricator system that enables wireline tool strings to be inserted into the wellbore under full pressure. A patented system enables the circulation of hydrocarbons back into the well, eliminating the need to transfer the fluids back to the vessel. The stack is adaptable to all subsea trees—vertical and horizontal—and is compatible with equipment from all the major manufacturers.

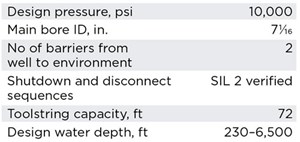

The closed-loop hydraulic system precludes fluid discharge to the sea. The hydraulics are located in the subsea stack—none on the surface—resulting in immediate control response, regardless of water depth. This is a critical feature, if an emergency disconnect is needed. The hydraulic pack can be changed to communicate with different types of subsea trees. Table 1 lists key technical features.

Four main components make up the stack. The pressure control head (PCH) creates a dynamic grease seal around the moving wireline. There are two mono-ethylene glycol (MEG) injection points for hydrate prevention and a tool catcher to prevent tool drop.

The upper lubricator package (ULP) is the connection point for the PCH and has a wireline cutting valve, which acts as a secondary barrier element (this valve is normally not used in wireline operations). The ULP also contains the circulation outlet. The ULP includes the lubricator tubular that provides the pressure lock for the wireline tool and carries the grease system for the PCH.

The lower lubricator package (LLP) is the connection point for the well control package (WCP) and provides a safety joint to prevent overload of the wellhead and tree. It also contains the controls equipment.

The WCP is the main well barrier. It can shear the wireline toolstring and coiled tubing. The WCP enables the hydrocarbons to flush back into the well and provides hydraulic energy to operate the WCP and subsea tree valves, as well as communication with the subsea tree functions. Equipment on the topside includes the ROV type umbilical reel, the umbilical clamp and a chemical injection unit.

PRODUCTION PERFORMANCE SOLUTIONS

FMC Technologies offers production performance software and hardware solutions designed to maximize uptime, production volume and total recovery. These resources provide operators with the information they need to monitor field operations in real time, so systems and assets can deliver optimal performance.

Real-time surveillance and predictive analytics. FMC Technologies’ Condition and Performance Monitoring system (CPM) is a real-time surveillance and predictive analytics software that is used to monitor the operation of subsea systems to confirm system health and asset integrity. The CPM system provides a graphical user interface, which displays the condition of the entire field and can switch to increasingly detailed views to investigate the root cause of any less-than-perfect condition. The CPM’s main value is early warning, so maintenance can be planned prior to functional loss. It includes a tool to easily view/find the equipment that needs operating and maintenance attention. The system is ideally installed onshore, but with an offshore interface to the subsea control system offshore.

Technical condition index (TCI). The CPM module uses available information from measurements and vendor data sheets to identify the current condition and performance. The output of the module consists of one or more values called the Technical Condition Index (TCI), which defines the condition/performance between 1% to 100%.

By normalizing the outputs from each CPM module, troubleshooting and identification of issues are simplified. Even though the CPM modules are based around failure mode identification, it is also useful to detect spurious behavior. This is achieved by comparing equipment behavior as a result of operator commands and deviations from known behavior. The complexity of the subsea production and processing equipment determines which CPM modules are needed.

CPM modules available include: sensor, hydraulic support system, actuators chokes/dosage valve, electrical system, flow meter, subsea processing systems, rotating process equipment (compressors and pumps), and stationary process equipment (separators, scrubbers, etc.).

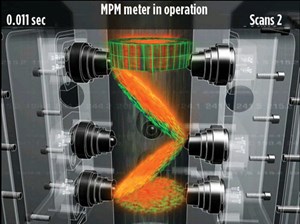

Multiphase and wet-gas metering. Subsea flow optimization and assurance tasks constantly change over time with variations in reservoir dynamics and fluid composition. Complexity increases when multiple wells or reservoirs are tied together into one large producing network. FMC Technologies’ Multi Phase Meters (MPM) employ tomographic technology to improve measurement accuracy and measurement range for multiphase meters for topside and subsea applications, Fig. 3. The MPM meter combines 3D broadband radio-frequency dielectric measurements with a gamma detector, ∆P venturi meter, pressure and temperature transmitters, to form a multi-modal tomographic system. Accuracy is ensured by using high-frequency electromagnetic waves (EM) on multiple planes (up to 27) and providing up to 200 readings per second.

The DualMode functionality allows automatic switching between multiphase and wet-gas measurements, when the wells change from predominantly liquid to predominantly gas. For slug flow regime with liquid slugs and gas pockets, the MPM meter switches between the multiphase and wet-gas modes up to five times per second. This ensures accurate three-phase measurements, even for this difficult, but quite common application.

The salinity functionality, integrated with the MPM meter, determines the water properties in multiphase and wet-gas, and automatically compensates for changes in water properties as this happens over time. This is particularly important for applications using water injection, or when early detection of water breakthrough is important.

The MPM meter is highly robust to fluid property changes. Even so, the in-situ verification functionality enables the MPM meter to determine the changing fluid properties, and eliminates the need for the operator to take challenging and expensive subsea fluid samples to further improve measurement accuracies. ![]()

- Middle East jackup fleet continues to shrink following Saudi suspensions (February)

- FPSOs, reliability and gas turbine air intake filtration (February)

- Rugged, explosion-proof computers safeguard offshore rigs (January)

- The evolution of remote-controlled FPSOs (January)

- Oil and gas in the capitals: Norway sustains the industry (December 2025)

- Riserless coiled tubing intervention cuts time and cost by half (December 2025)