Simulated training for next-gen electric ROVs and drivers

Simulation, depending on your definition, has been around for centuries. Computer simulation, itself, has been around since at least the Manhattan Project during World War II, and possibly before, depending once again on definitions. Today, computer simulation is used to greatly reduce engineering costs and risks of subsea projects. By utilizing a rigid body simulation and applying unique solutions to problems, users can significantly reduce project turnaround time and cost, as well as eliminating problems and safety issues encountered later in a project.

The definition of simulation in this case refers to rigid-body, six-degree-of-freedom simulations of subsea operations, complete with realistic 3D graphics, and some sort of hardware interface for controlling the simulation. There are many other varieties of simulation—finite element simulation, for example—which have their place in the development of subsea equipment but are outside the scope of this article.

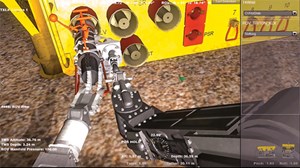

The software in question, VMAX Simulation Software (Fig. 1), is similar to a flight simulator (for a point of reference), except that the pilot is flying a remotely operated vehicle (ROV) rather than an airliner.

In fact, the analogy of a flight simulator is quite apropos, as flight simulators can be large, complex and expensive affairs, requiring a specialized facility or a simple system installed on a home computer that uses off-the-shelf joysticks, which can come in many sizes and complexities. The VMAX ROV Simulation can vary to the same degree, being a big and complex system with real ROV hardware connected, or a simple desktop system with off-the-shelf joysticks used to fly the simulated ROV.

VMAX comes complete with a variety of ROV scenarios designed to test pilots’ skills, such as tether management, manipulator control and tooling operation within realistic operational conditions, Fig. 2. With these scenarios, VMAX can be utilized in a training capacity for ROV operations companies. It can also be utilized by subsea engineering teams for modeling and verification of procedures involving intervention tasks for subsea equipment utilizing its custom-scenario creation capabilities.

The latest version is designed to integrate with next-generation electric ROVs, such as Forum’s XLe Spirit, launched in 2018. The new lightweight and ergonomically designed eROV hand controller console also can be interfaced to VMAX, to allow pilots to be trained in the use of the new console.

SIMULATION BEFORE ACTIVATION

Subsea oilfield projects are being subjected to many of the same pressures that the remainder of the oil and gas industry is facing. The “new normal,” as we have all become used to hearing, has required all the players in the subsea industry to work hard to cut costs, wherever and however necessary. The basics of subsea operations have not changed, however, as it still requires an ROV to install and interact with a set of structures and apparatus designed to collect oil from beneath the ocean floor. The devil, as they say, is in the details. The act of operating an ROV, potentially thousands of meters below the surface of the ocean, is a difficult art form. There is no kinesthetic feedback (the feeling of the motion of the submarine), the pilot is generally seeing the world through a predefined set of camera views, and the environment provides less-than-ideal lighting and visibility conditions.

If just operating the ROV is difficult, then having equipment that does not consider the size, shape and operational qualities of the ROV makes the job that much more difficult. Designing equipment for this environment is already a difficult task, as seawater, itself, is a harsh environment.

Seawater conducts electricity, corrodes metal, and carries various forms of life that like to cling to human-made structures. Additionally, seawater is 10 times the density of air, which means the equipment must deal with huge amounts of pressure beneath the surface of the waves. Water also absorbs and distorts light, which means that the environment is dark and difficult to see in, even with high-intensity lighting.

Engineering teams in charge of designing equipment for the subsea environment understand the basic nature of the subsea environment, the high-pressure and caustic environment, but often do not have a full understanding of ROV operations. A simple example is the location of a grappling handle on a subsea tree. The grappling manipulator is almost always mounted on the left side of the ROV. This manipulator, usually a rate-controlled robotic arm, is used to anchor the ROV to the equipment that the ROV will be working with. Often, engineers will design a handle for this manipulator to be on the right side of an access panel, either out of a desire for symmetry (matching a left-mounted handle) or the belief that this handle will facilitate access to interfaces on the right side of the panel. At best, this additional handle will be useless; at worst, it will inhibit useful actions on the panel.

There are countless other examples where learned knowledge would be lacking in a subsea engineering team, as many of the engineers will have no direct experience with operating subsea. Gaining this knowledge can be difficult and expensive, as it is usually acquired through feedback from an executed project or institutional knowledge that is difficult to pass on.

CUSTOMIZED SCENARIOS

Simulation opens up a new way to gain operational knowledge, as it is relatively inexpensive to have an engineer utilize a desktop simulator to fly an ROV around. VMAX offers a set of generic training scenarios that can allow an engineer or pilot to familiarize themselves with basic ROV operations, Fig. 3. However, these scenarios are, by design, generic and focused on learning a type of operation, rather than analyzing a specific project. For example, there is a scenario for installing a rigid jumper, but the operation is focused on torque-tool and hotstab operations, rather than the specific layout of a particular field, in which there may be additional obstacles that make the operation more difficult.

Where the simulator has shown its true power is in tailoring circumstances for a particular project. Creating specific situations with models of the actual equipment being used for a subsea project allows the engineers to truly see how the ROV will interact with the equipment they have designed, and in the environment that the equipment will be in. Simulation will quickly show when another piece of equipment is in the way of operating a certain ROV panel on a manifold, which might not be obvious when designing the panel.

VMAX, as well as other simulators, has been used for such analysis for years. However, this usually required specialized personnel and some significant time to prepare the simulations. VMAX required at least novice level computing skills to build even a simple scenario. Additionally, VMAX and other simulations required 3D modeling experience to properly prepare models for simulation, as engineering models are usually too detailed for real-time simulation. The 3D software specified in this article is animation software and not 3D CAD software.

Most engineering teams do not have these skills natively and must recruit additional personnel or outsource simulation, if this is required. In fact, some simulation software packages must be built by the vendor, itself.

IMPROVED VERIFICATION THROUGH COLLABORATION

Forum Energy Technologies and a world-leading technology provider worked together to build new processes, to revolutionize the use of the simulator.

To verify equipment, the client had utilized animation for several years. This involved producing hundreds of still shots of a modeled ROV performing tasks for a subsea structure. These still shots were created by puppeteering the ROV around the structure to the correct locations. Despite years of optimizations, this system still took far too many hours to create reports and continued to present several additional limitations.

The client approached Forum to be part of a project that required simulation for delivery. Though the company examined other simulators, VMAX was selected, due to a successful project executed for the company in Brazil, its track record, and the fact that scenario development could be brought internally without having to use VMAX personnel. However, before this bid was even complete, VMAX and client teams realized that simulation could perform verification faster than the current animation pipeline. With this realization, the companies began to work together to revolutionize their verification system.

Discussions began immediately, focusing on using the customer’s personnel for the creation of scenarios. Additionally, the entire process, including onboarding and training, had to fit within the timeframe allotted on the current project for verification. With these constraints, the entire team began to work through a process that included optimization of model prep, organizing the model repository and pipeline, and simplifying the interface of the simulation, so personnel with little-to-no programming experience could create scenarios and fly the operations.

As part of this first project, a number of hours were purchased from VMAX, along with a number of licenses. This time was then spent working with the client’s animation specialist and being directed by a system engineer to begin the process. First models were prepared for simulation, and then scripts were arranged for the animators. While reducing interface complexity, the scripts were used by the VMAX engineer to move models into place and add custom functionality to the simulation.

It cannot be overemphasized how important the reduction in complexity was. The resulting scripts allowed engineers and animators with little or no experience in programming to simply change a data value at the top of the script, and completely change the behavior in the simulation. The scripts were modified, based on feedback and ideas from the team, which greatly improved the overall usefulness and speed of scenario creation.

An example of how the team worked together to improve the simulation speed and efficacy was ROV tooling. Originally, it would be modeled in a receptacle, which would be attached to the ROV and, during simulation, the pilot would use the manipulators to retrieve the tool and utilize it with the equipment. If the ROV needed different tools, the pilot would exit the scenario and select different options or a different scenario.

Following feedback and ideas from both parties, a method was created in which a complete set of tools would be added to the scene. The names of the tools would then be added to the script in a clearly marked data section. Once the scenario was loaded, a menu was made available to the pilot, which allowed him or her to select which tool was needed, and it would then appear already in the jaw of the manipulator of the ROV. This allowed the integrated solutions provider to verify the use of all the tools, as well as not having to retrieve tools using the manipulator.

At the completion of the project, the team had reduced the time for evaluating large structures to approximately one week per large structure. This was a large financial savings over previous projects of similar scope. The following project was completed even faster, with more functionality and easier processes created. Additionally, the company performed most of the verification projects with minimal support from Forum personnel.

The firm has found additional benefits to using simulation. For instance, the simulation can be recorded and replayed as a full 3D representation, allowing views from any camera on the ROV, as well as free-camera views that can look from any angle. Prior to improved verification, if the system team brought up potential problems with the engineering team, it would be difficult to prove there was a problem, as only still images were available. Replaying the simulation, or even running it with the engineer present, has allowed the systems team to show an operation to be difficult or impossible. Stills could not show the in-between states of the manipulators and what was required to get an ROV into place, to operate on a given piece of equipment, but the simulation can show all operations in-between.

The speed achieved in preparing simulations and verifying equipment leads toward a shift in the overall engineering process. Previously, due to the time and effort involved, equipment was not validated until it was almost time for the equipment to be manufactured. If an issue was found, it was extremely costly to modify the equipment, and so there was considerable resistance to any findings brought by the systems team. The systems team is now beginning to push the simulated validation offering earlier in the project lifecycle, to analyze pieces of equipment at a nascent design phase, when corrections are cheaper. With these changes, the organization strives to reduce project execution times to an even greater extent than already achieved.

The global technology provider already has seen the benefit of its expansion in usage of VMAX. There has been a reduction in project validation costs of approximately 50%, and overall execution time reduction of approximately 60%. Other benefits have included the increase in understanding of the engineering groups, as they get a better idea of what an ROV can and can’t do, thereby improving the basics of design.

VMAX has seen its product improve as a result of interaction with the customer. Utilizing feedback from the team, VMAX personnel have embarked on a quarter-by-quarter continuous improvement scheme to enhance features of the simulation library. These features, coupled with improvements garnered from earlier projects, are geared toward reducing the learning curve of the software and thus removing barriers to new people utilizing it. This will allow easier and further adoption through the client and other companies and groups in global oil and gas.

- World Oil’s Deepwater Development Conference approaches with great momentum (February 2025)

- The future of connectivity and automation in wellsite operations and workflows (January 2025)

- Digital transformation: Next-generation flexible control system modernizes wellsite operations (January 2025)

- Advancing MPD operations with integrated riser joint technology (January 2025)

- Digitalizing training management and delivery (December 2024)

- Accessing wells beneath deepwater facilities (December 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)