Unity develops new P&A technology, enabling safe pressure testing of suspended mudline wells

ABERDEEN -- A pioneering new method of pressure testing suspended mudline wells from a vessel, prior to P&A activity, developed by Unity, is set to deliver improved safety and cost savings following a successful project for Spirit Energy.

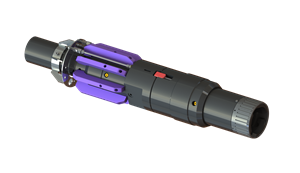

The Aberdeen-headquartered company’s Temporary Abandonment Cap Test Tool (TACTT) was deployed to support an end of life project located in the Southern North Sea.

It is the first technology of its kind, which is able to seal on to any type and size of temporary abandonment (TA) cap, pressure test the seal to ensure well containment, then test and vent pressure from below the TA cap and leave a reliable secondary seal in place. It can be cable deployed from a vessel through open water, rather than using a rig, providing significant cost savings.

During the project for Spirit Energy, the TACTT was deployed from a vessel, latched and sealed on to the TA cap and the seal was pressure tested. A second pressure test was then performed to provide verification of zero pressure under the TA cap’s back pressure valve. Once integrity was confirmed, this allowed the operator to safely continue with removal of the cap and complete their P&A operations.

The technology allows the operator to understand the amount of pressure accumulation below the TA cap and to accommodate this in their plans for decommissioning, either continuing with vessel-based intervention or leaving the TACTT safety valve in place and returning with a rig at a later date if necessary. Vessel rather than rig-based P&A work is faster and more cost effective and Unity’s technology can help to enable this type of intervention by safely confirming no back pressure for well re-entry.

A recent report by the Oil and Gas Authority estimated that 45% of all decommissioning expenditure in the UK Continental Shelf is through P&A of wells and the industry is currently striving to reduce this spend by at least 35%. It is generally acknowledged that vessel-based intervention can save between 30%-50% in costs compared to rig-based intervention.