Silverwell deploys successful dual completion gas lift to optimize production for “major” oil company

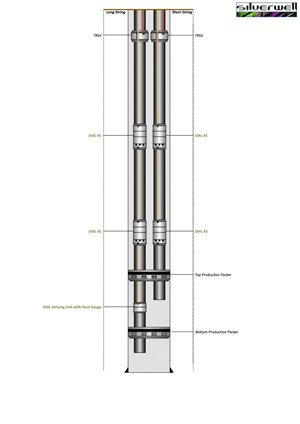

(WO) – Silverwell Technology Inc. has announced a successful dual completion gas lift deployment using its (DIAL) production optimization system for a major oil company in the Eastern Hemisphere.

This technology opens new reservoir development opportunities for the operator. DIAL will save significant capital expenditure (capex) by avoiding the drilling of additional wells and will accelerate production. It will also reduce operational expenditure (opex) by eliminating well intervention costs.

DIAL enables production and efficient gas lifting from both strings in the well. The system, which is used by operators around the world both onshore and offshore, integrates in-well monitoring and control of gas lift well performance with surface analytics and automation to continually optimize gas-lifted fields, remotely and without intervention.

With traditional gas lift methods, it can be challenging, or even impossible, to effectively produce both completed zones in a dual-string gas-lifted well, due to the complexity of controlling gas injection using conventional pressure-operated valves. The string dedicated to the formation with the lowest productivity and reservoir pressure tends to divert the gas from the other string.

Additionally, fluctuating casing pressure, unpredictable temperature gradients due to the proximity of the two strings, and an inability to individually control the injection rates for each string make simultaneous production optimization extremely difficult.

DIAL overcomes the production and operations constraints of traditional gas lift practices in dual completion wells. Gas lift injection rates can be adjusted for each string without the need for well interventions. DIAL also allows the simultaneous recording of downhole temperatures, pressures, and injection rates at the gas injection depth in each string.

“Gas lifting both strings enables operators to achieve increased production from their dual string wells, while saving them the capex of having to drill additional wells. DIAL enables the recovery of by-passed reserves. It also allows easy adjustment of the gas lift parameters as reservoir conditions evolve over time, such as increased water cut or lower well productivity,” said Steve Faux, Operations Manager.

Darrell Johnson, Silverwell CEO, commented, “DIAL is pushing the boundaries of gas lift operations and is bringing gas lift into the digital era. For dual completions, it greatly enhances production and lowers capex by eliminating the need to drill two wells. It allows operators to reconsider their field development programs in light of their ability to effectively gas lift in a dual completion environment.