Deepwater technology: How to simplify and optimize subsea operations with remote digital technologies and data-driven solutions

In the subsea world…

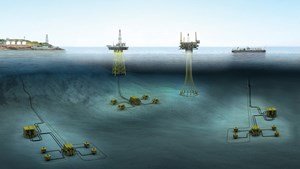

Subsea operations are inherently complex, due to a wide range of challenging factors including environmental conditions, equipment reliability and personnel safety. This requires operators to possess a comprehensive understanding of the associated risks and navigate numerous processes from a host of stakeholders, Fig. 1.

The use of robust and reliable digital technologies, interconnecting systems, processes and advanced sensors is crucial. This aids in leveraging data more efficiently, understanding it deeply to manage risks, maintaining uptime and reducing cost.

Digital enablement through the years. To comprehend today’s digital frontier, we need to recall its origins. Digital enablement began to evolve with data centers in the 1980s. Significant investments and efforts were directed towards data aggregation, and standardization and collaboration took place to leverage value out of data in a very demanding market.

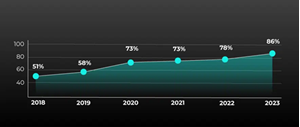

At the current rate of growth, the high volume of information acquired has reached the limits of practical application, leading to devaluation of raw data and the point where opportunities will lie in new and better ways to exploit it. The adoption of affordable technology plays a crucial role in addressing this overwhelming complexity and breaking the created silos, Fig. 2.

The three pillars of simplification. Efforts to simplify and optimize subsea operations center on three key pillars:

- Connectivity: Linking diverse data streams into one cohesive source simplifies access, offering a holistic view of assets and facilitating data-driven decision-making. This is particularly valuable for subsea operations spanning multiple locations and involving various teams and disciplines.

- Visibility: Having insights throughout the operational lifecycle—combined with remote operations and monitoring—paves the way for a fully digitized, real-time overview of subsea infrastructures.

- Operational excellence: Achieving this involves refining processes, continuously monitoring asset health and using advanced remote communication tools. These steps aim to streamline operations and provide on-site personnel with tools to work more efficiently and reduce emissions.

More affordable and easier to use. Digital technologies’ affordability has been a game-changer. Ranging from data analytics and AI-driven predictive maintenance to remote monitoring and blockchain for supply chain management, these tools have significantly enhanced operational efficiency and cost-effectiveness.

The affordability of these solutions has expanded their accessibility to a broader spectrum of companies, irrespective of their size or financial resources. As a result, smaller players in the industry can harness the power of data-driven decision-making, reducing downtime, optimizing production and minimizing environmental impact.

This democratization of digital tools has not only improved the overall competitiveness of the sector but has also accelerated its journey towards sustainability and resilience in an evolving energy landscape.

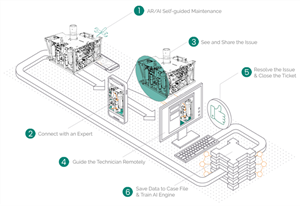

Baker Hughes Subsea Projects and Services utilized a platform that fused next-generation digital tools with traditional offshore operations, enhancing experiences and bolstering relationships with customers and partners, Fig. 3.

Examples from the field. Several real-world examples illustrate the merits of implementing remote digital technologies in subsea operations. From remote BOP stack inspections to wellhead installation without nonproductive time, the results are remarkable. Cost avoidance, reduced carbon emission and increased operational efficiency and improved communication between the two are all part of the success story.

One example is a wellhead installation offshore Angola—including 30-inch conductor wellhead housing and 18-inch high-pressure wellhead housing—which was completed using remote support for the onboard team without any NPT. Aided by a subject matter expert from the 24x7 remote support center, this task was completed in half the anticipated time. The 24x7 remote support center helped drive collaboration between functions and data handling, create a centralized knowledge bank and further develop best in class software and troubleshooting at a distance.

Another example during the COVID pandemic saw a platform vessel survey executed with the aid of low bandwidth augmented reality tools, Fig. 4.

"The remote app was very simple and intuitive," said the project team. "I believe it can be extremely useful, as it greatly reduces communication time when it is necessary to see the situation. I would be happy to use this again and would absolutely recommend this to others."

In this example, Baker Hughes assisted an operator in managing data from multiple fields acquired over time, Fig. 5. The initial project phase involved 40 years of data from more than 150 wells, including OEM information, maintenance history and associated documents. The operator also sought a timely and cost-effective well integrity monitoring solution.

The tailored solution was implemented in four months, digitizing all fields and integrating information related to the installed base. This setup provided real-time data on their installed base and tooling, and it included integrity monitoring response plans.

This resulted in an estimated reduction of $3 million in costs and 600 metric tons of CO2 equivalent in emissions over the project’s duration and a 15% increase in operational efficiency. Moreover, the platform improved communication and collaboration among teams, fostering even greater efficiency.

The next step involves unlocking the obsolescence management applications, tracking asset health, implementing a preventative maintenance toolkit and enabling a range of diagnostics and prognostic capabilities.

Looking ahead for sustainable growth. Digital technologies have transformed how we respond to a crisis, execute key projects and prevent future issues. They are used across the industry to achieve greater economy, efficiency and carbon reductions.

For Baker Hughes, the right, feature-rich and scalable tools leverage data and analytics to enable a collaborative approach to proactive servicing, extend asset life and reduce OPEX.

These tools also play a critical role in breaking down data and organizational barriers, reducing failures and associated costs and contributing to decarbonization efforts.

That’s why companies, including Baker Hughes, are committed to maximizing all that the technology efforts, whether through remote service centers, or during project execution, or for routine operations. The focus remains on accelerating adoption and progression with energy providers and partners to industry challenges and intricacies.

ABOUT THE AUTHOR

Fouzi Bouillouta is the subsea program leader for Baker Hughes, an energy technology company. Before joining subsea projects and services, he worked on a variety of digital and remote operations projects contributing to demanning efforts and improving performance for operations and reducing field carbon footprint, before moving to reservoir technical services management role.

His current role leading the engageSubsea platform at Baker Hughes allows him to leverage years of experience in implementing digital technologies for the energy industry, understanding complex operational challenges, and translating these into effective optimization solutions.