Offshore Europe: Balmoral surges forward on multiple energy fronts

(The following interview is another segment of World Oil’s extended coverage of topics, speakers and companies at Offshore Europe, held Sept. 5-8.)

This is a heady time for Aberdeen-Scotland-based Balmoral Group. Specializing in buoyancy, protection and insulation solutions, the firm is optimistic about the near-future, as it sees a resurgence of offshore oil and gas activity globally, as well as an opportunity to tap into the growing market of renewable energy offshore. Accordingly, World Oil visited with Balmoral’s Group Public Relations Manager Steve Gibb at Offshore Europe, just as he was wrapping up his career with the company (more on that farther down in this story).

“We’re optimistic about business in the near future, as we see growth opportunities in both our traditional oil and gas lines, as well as ventures into renewables,” said Gibb. “I’d say that 40% of our business is from offshore wind, and 60% comes from oil and gas. We’ve been adapting our technology, in terms of the offshore wind sector.”

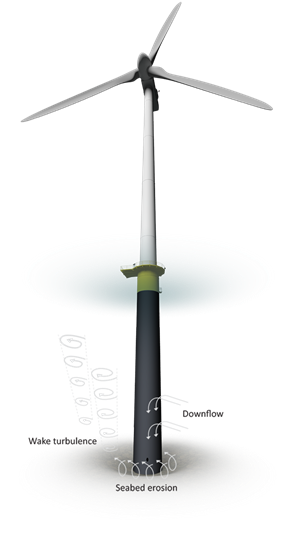

HexDefence system. Indeed, Balmoral has adapted and transitioned several of its proven buoyancy and protection solutions for use in the fixed and floating offshore wind sector. Now, following extensive research and investment, the company has brought a completely novel and globally patented product to market which aims to drastically reduce scour phenomena (Fig. 1) around fixed wind turbines that cause seabed erosion and a reduction in foundation strength and stiffness.

To address these issues, Balmoral developed Balmoral HexDefence™, an exclusive scour protection system that integrates seabed protection and flow reduction to minimize offshore operational costs and potential cable failure.

The HexDefence structure eliminates the requirement to dump rock, instead providing a non-invasive approach to protecting the monopile and the immediate surrounding area. The lightweight advanced composites construction and streamlined installation method makes it easy to install without the need for additional vessels resulting in an improved carbon footprint for all operations.

Additionally, the system can be used with antifouling coatings and does not require special equipment for end-of-life recovery. Following positive discussions with leading wind farm developers and industry bodies Balmoral earlier this year brought the product to market as soon as possible.

In-line mooring buoyancy. Another example of Balmoral’s innovation is In-line mooring buoyancy developed for floating wind and SURF sectors.

Balmoral’s in-line mooring buoyancy system is designed to secure floating wind turbines and other structures to a seabed anchor while providing uplift to the mooring line. It also can act as a connection point between the bottom and top sections of the line while allowing trajectory and tension to be controlled within the water column. Traditional mooring systems feature a pendulum fixture, using a tri-plate and buoyancy module secured via a padeye at the base of the steelwork, which gives an offset center of buoyancy.

Balmoral’s engineers identified the biggest vulnerability of this system was fatigue failure, due to the offset loads so, to mitigate against this and change the load transfer characteristics, they developed a proprietary in-line mooring buoy. The company’s in-line system features a dynamic connection interface that allows the different sections of the mooring lines to be tethered securely and responsively without adversely loading the buoyancy structure.

Company outlook. The HexDefence system and In-line mooring buoyancy system are just two examples of recent Balmoral innovation, noted Gibb. “It’s very exciting stuff, and there has been a lot of interest from developers.” Still, acknowledged Gibb, the company’s biggest item remains buoyancy products for oil and gas.

Balmoral, he said has enjoyed an increase in business from industry hot spots like Brazil and Guyana. All of the firm’s manufacturing is done in the UK. Indeed, a new composites manufacturing plant has been opened recently, quayside in Montrose.

The company, said Gibb, is “still very much a privately owned company.” Balmoral has some 600 people, with six locations outside the home office in Aberdeen, including an office in Houston. While confirming that the offshore sector, overall, is better than a year ago and improving—helped by wind-oriented work—Gibb said the company’s biggest challenge remains getting enough people to fill all its job slots.

Accordingly, he had a prediction for the offshore wind sector’s health and progress. “The offshore wind sector will need the experiences and skills of people in oil and gas to get things done,” said Gibb. “We need experienced people to bring new younger employees up to speed.”

Gibb’s retirement. During World Oil’s visit with Gibb at the Balmoral stand during Offshore Europe, he let it be known that his last day at Balmoral before retirement would be Sept. 14. Accordingly, we asked him to provide us with a few final career thoughts, as follows:

“It has been an enormous pleasure and privilege to have been a part of this fantastic industry for almost 40 years and to have worked with such a progressive and innovative company such as Balmoral,” said Gibb. “There have been many changes in the sector over those decades, and the energy transition that’s taking place now is the latest revolution for the industry and everyone involved in it.

“I’ve been fortunate to have met scores of wonderful, creative and clever people in my career,” continued Gibb, “and I will be sorry not to have regular contact with them but, naturally, I will be maintaining contact with those good friends I have made over the years. So, it’s cheerio for now but not farewell and thanks for the memories, y’all!”

And to you, Steve Gibb, we wish you great health and happiness in retirement and best wishes for whatever activities you may pursue!