MCEDD 2024: Efforts to electrify deepwater operations increase

As Day 2 (April 10) of the MCEDD 2024 conference (Marine, Construction & Engineering/Deepwater Development) got underway, one of the more fascinating sessions took place. This lead-off session was entitled, “Electrification of Subsea Developments and Brownfield Infrastructure.” Presenter/panelists included Alexander Fugelsan, CEO at FASTsubsea; Elisabeth Eikeland, Sales Engineer, and Fredrik Wadel-Anderson, Processing S&C Norway & Emerging Markets Global Manager, OneSubsea, an SLB company; and Antoine Marret, Technical Manager, and Pierre d’Huart, Head of Offshore Technological Development, Saipem.

The various speakers addressed what is one of the more intensive efforts in upstream oil and gas—electrification of deepwater assets. Speakers from the three firms identified where the effort needs to be concentrated, what their firms are doing individually to offer solutions, and where they think the process is headed in the future.

Subsea boosting. Leading off the discussion was FASTsubsea’s Fugelsan, who spoke about the work being done with subsea boosting and the efficiencies that this subsea pump technology can bring. “Subsea boosting contributes to cost-savings and reduced CO2 emissions, yet it uses 40% to 80% less energy than gas lift to produce the same barrel of oil,” said Fugelsan. He then asked, “if that’s the case, then why are there not more pumps? And the answer is simply habits, complexity and cost.”

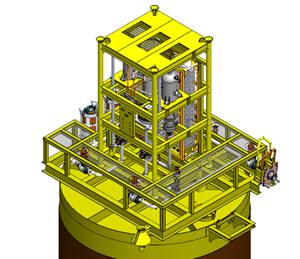

Accordingly, he added, FSubsea and OneSubsea got together and created FAST subsea. “Simpler operation equals lower cost and more reliability.” In addition, he pointed out, there is less total equipment and steel required with subsea boosting, (Fig. 1). “So, there’s a topsides weight savings of anywhere from 100 to 500 tons.”

The ongoing work on this technology has resulted in a JIP that includes Petronas and Equinor. And another aspect, in turn, is Hydromag, which has a magnetic coupling system. This technology makes pumps simpler and truly modular.

Fugelsan cited a case study involving Petronas, whereby subsea boosting has been tried successfully. “This site involved tie-backs in the Sabah deepwater area offshore Malaysia,” explained Fugelsan. “It’s proven to be a mor sustainable pump system.”

Subsea power hubs and SPS’s. Touching on another electrification aspect were Eikeland and Wadel-Anderson of OneSubsea. They discussed Subsea Power Hubs in the context of subsea production systems (SPS’s), an effort featuring participation from their firm (70%), Aker Solutions (20%) and Subsea 7 (10%). Eikeland noted that OneSubsea/SLB has had a large SPS and processing footprint with respect to deepwater operations. She said this is not surprising, given that the firm offers business lines for subsea production systems, processing systems, umbilical and cable systems, and subsea services.

Eikeland further noted that the Subsea Power Hubs (Fig. 2) can be invaluable when dealing with longer tie-backs in deepwater areas. “The longest tie-back for a subsea pump came in 2018, with TAQA Energy and others,” she said. “And now, in 2024, we have the longest tie-back for subsea compression at Ormen Lange (Shell) field.” This aspect of Ormen Lange takes on greater significance, she continued, because the field provides about 27% of all the natural gas used in the UK. And, not surprisingly, more than 5 million hours of operations have been accumulated there.

There are three notable aspects to subsea power, explained Eikeland, and those include harvesting, manifolding and converting. Picking up that thread, Wadel-Anderson said the short-term goal of subsea power development is to “provide efficient transmission of the power that supplies deepwater oil and gas facilities. The long-term goal is to establish an energy connection point for multiple energy carriers.” Accordingly, a wide range of solutions is underway.

Wadel-Anderson went on to say that the benefits of going subsea include the saving of topsides space and weight; not having additional operational exposure; and employing stable and efficient cooling. He also explained the “technology bricks” involved. For instance, in a 1,000-m example, some the pieces or “bricks” required include a transformer, proven subsea methods and materials, and subsea electrical connection system. The latter includes both wet-mate and dry-mate connectors.

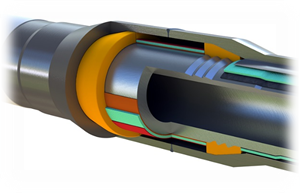

Pipe-in-pipe operations. Meanwhile, Saipem’s Marret and d’Huart spoke to the development of high-performance, direct electrical heating/pipe-in-pipe (DEH-PIP) operations. Noting that offshore development trends, particularly in deep water, require enhanced production, cost-effective architecture and simpler solutions, they said this has led to increased challenges.

DEH-PiP is a well-known, field-proven technique for subsea flowline heating, but it shows a relatively poor electrical efficiency, compared to emerging heat-traced PiPs. Hence, Saipem engineers over the last several years have analyzed the heat losses within conventional DEH-PiP, and then have worked to design a new outer pipe to decrease dramatically its impedance. A strong effort was made to build an accurate electrical model for the High-Performance DEH-PiP, and finally full-scale electrical tests were carried out on a representative prototype to validate the model.

As outlined by Marret and d’Huart, the DEH-PIP operating principle involves current flowing into inner pipe, producing heat by Joule effect, and returning through outer pipe in a closed loop (clear electrical path), This works as a coaxial cable, with both skin and proximity effects. As Marret said, this gives “an intrinsic reliability. There are no cables or intermediate electrical connections.”

But then, to go a step further, Enhanced (high-performance) DEH-PiP (Fig. 3) operates with two additional simple features. These are an aluminium liner and electrical insulation. As explained by d’Huart, the main benefits of this improved DEH-PIP are reduced Ohmic losses in outer pipe; higher electrical efficiency, where it goes from 60% to 90%; a reduced operating voltage, down to around 40%; a simpler power supply chain; and the ability to support longer tie-backs.

Along with the work on High-Performance DEH-PIP, Saipem’s innovators have worked on Wedge Shear Stops, which are a polymer alternative to metallic intermediate bulkheads. Marret said that these composite wedges serve as a mechanical link between inner and outer pipes. These Wedge Shear Stops maintain electrical insulation continuity between inner & outer pipes, provide safer offshore operations (lighter), and required reduced installation time.

Looking at overall development of these two items, d’Huart said that most of the testing of the enhanced DEH-PIP has been completed, while testing and proof of the Wedge Shear Stops should be finished by fourth-quarter 2024.

In summation, what differentiates Saipem’s High-Performance DEH-PIP is Increased electrical efficiency, lower power consumption and a simpler power chain; higher power output over long tie-backs; larger pipeline diameters and deeper waters; highest reliability, with no cable or intermediate electrical connection; and unique engineered linear power for cold area management.