OTC Spotlight on New Technology Awards: Offshore industry innovates despite muted activity

Offshore investments may still be slow to accelerate, but that hasn’t stopped companies from ramping up R&D efforts to create a safer, more efficient and more productive offshore industry. The results of these endeavors are new feats of engineering that could enable high-cost operations, such as those in deep water and harsh environments, to better compete with short-cycle shale activity. To recognize companies that have achieved great strides in this sector, the Offshore Technology Conference has awarded 17 companies its Spotlight on New Technology Award. ![]()

RISER FLEXIBLE JOINT

LORD Corp. has developed a high-pressure flexible joint for well interventions, completions and workovers. It can be used in place of a traditional stress joint to contain fluids within the riser, react the tension (designed for 400 metric tons/900 kips) in the riser, and accommodate the motion of the vessel (up to a 10° cocking angle). It features a 7.22-in. internal bore diameter, allowing passage of workover and intervention tools. The flexible joint is rated to 10,000 psi and hydro-tested to 15,000 psi. Additionally, safety factors were verified with an ultimate burst pressure of 32,000 psi. This flexible joint utilizes a unique dual-bearing design, where each bearing is comprised of multiple layers of elastomer bonded to spherical reinforcements. The seal bearing is optimized for high-pressure containment and fluid resistance, while the load bearing is optimized for low rotational stiffness and fatigue strength.

The entire flexible joint is just over 5 ft in height, allowing smaller intervention vessels to operate a top-tensioned riser without a stress joint or a telescopic joint, enabling higher-pressure interventions, more cost-effectively than a drilling rig.

MOTION-COMPENSATED GANGWAY

Nicknamed ‘Icemann’, Ampelmann’s N-type gangway system is designed to safely and efficiently transfer crew in extreme ice states and temperatures as low as -18°F. The fully enclosed and insulated system is certified under winterization design code DNV-GL-OS-A201 and is operational year-round in sea states up to 3.5-m significant wave height, and wind speeds up to 38 knots. It comprises active motion compensation with 360° rotation, which is controlled from the vessel. This ensures flexibility in platform landing locations and directions for the transfer of up to 20 people. It has a maximum gangway length of 32 m with a telescopic scope of 11 m and a footprint of 11 m x 11 m. Total peak power consumption is 1 mW.

The gangway and transfer deck are fully protected with an icephobic cover to limit the growth of ice and reduce the effect of wind chill. It is purpose-built to operate in areas such as sub-Arctic Norway and Canada, as well as areas of the Caspian Sea.

AUTOMATED MPD SYSTEM

As a proven technique to enhance well construction, MPD enables precise control of the annular pressure throughout the wellbore. The GeoBalance system from Halliburton allows an operator to control wellhead pressure through the use of a real-time wellbore hydraulics model and specialized equipment. This model, calibrated with real-time drilling data and combined with the the system’s proprietary algorithms, help optimize drilling conditions and dynamically monitor for kicks, losses and wellbore stability.

SUBSEA WET INSULATION

ACS HT-200 from Aegion Coating Services is an ultra-high temperature, subsea, wet insulation system for pipelines, risers, field joints and subsea equipment with operating temperatures as high as 400°F. This end-to-end deepwater solution is comprised of an anti-corrosion coating covered with an insulation layer and topped with a tough polypropylene exterior. The two-part insulation materials can be mixed and injection-molded rapidly to produce line-pipe joint lengths of at least 82 ft, large single castings for subsea equipment, and field joints with a cycle time under 5 min.The development of the production-ready system took more than three years. The line pipe, field joint and subsea equipment insulation layers feature Proxima HTI resins, a line of thermoset norbornene polymers developed and supplied by Materia, Inc., in Pasadena, Calif. Full-scale production began in September 2016, and the first order of line pipe was completed in July 2017.

AZIMUTHAL LITHODENSITY SERVICE

Halliburton’s 9½-in. Azimuthal Lithodensity (ALD) service is reportedly the industry’s only LWD service which provides deepwater operators with real-time density measurements and high-quality image logs in boreholes up to 17½-in, according to the company. Previously unobtainable, these LWD measurements help operators enhance reservoir understanding and make informed geosteering decisions immediately after drilling.

The company has run the service more than 10 times in deepwater commercial wells in the Gulf of Mexico, for large E&P operators, with over 1,000 operating hours. Results show consistent data quality and repeatable performance from well to well, leading to high confidence and reduced well time and costs.

MOORING RELEASE TECHNOLOGY

A full description of this winner from Delmar Systems, Inc., is available in the Tech at OTC section.

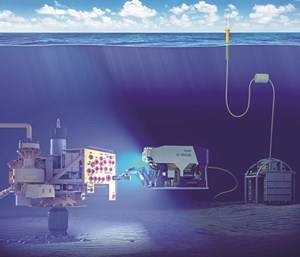

SUBSEA WATER TREATMENT

The Seabox subsea water treatment system from NOV enables treatment of raw seawater directly at the seabed. The water is then pumped straight into the injection well for pressure support, sweep and increased recovery. This allows operators to optimize water flooding by using high-quality water, at any time and location. Moving water treatment and injection from topside to subsea creates more ways of developing new fields and optimizing existing fields, allowing operators to simplify the entire process—enabling better cost and energy efficiency, improved reliability, and reduced emissions.<

The system, using a large GRP structure at the seabed, treats seawater with electrochlorination and hydroxyl radicals with a residence time of more than an hour. At the same time, 99% of particles larger than 15 microns will be settled out. The resultant water is disinfected and of higher quality than the water treated by traditional topside solutions.

FIRE-RESISTENT ELECTRICAL PENETRATOR

The FlameGuard P5-200 from Teledyne Marine is a flame-proof ceramic electrical penetrator for use as part of the fire resistant envelope of an offshore surface wellhead and Christmas tree system. The penetrator is a key element in a larger feedthrough system being qualified to provide three-phase power to downhole electrical submersible pumps (ESPs) in offshore dry trees. The penetrator is rated as fire resistant in accordance with API.

This new penetrator is rated to 5,000 psi working pressure, and exposed to 7,500 psi test pressure. The penetrator’s nominal operating envelope includes temperatures ranging from 4°F to 250°F. The technology can be adapted to achieve higher operational pressures and temperatures.

INTELLIGENT CORING SYSTEM

Small Business Winner. The Intelligent Coring System (ICS), from Norway's CoreAll, is an instrumented core drilling technology, designed to be run on conventional drill pipe. The BHA features a conventional mud pulse telemetry system, a power generation system, wired core barrels and a logging-while-coring sensor sub. The current version of the sensor sub logs comprises gamma ray logging, dual-level resistivity measurements on the core sample, temperature, tri-axial vibration sensors, and a novel core barrel stall detection system—along with system diagnostics. Formation parameters are measured close to the bit, approximately 15 in. from the bit face for the first sensor set.

Data are transmitted to surface in real time and provide personnel on the rig with essential information about the subsurface while the operation is still ongoing. The system is available only with a 7¼-in. body OD, designed for 8½ to 9½-in. hole sections. With this setup, core samples will have a 3-in. diameter.

E-ROV SYSTEM

Oceaneering’s self-contained, battery-powered, remotely operated vehicle (E-ROV) system increases operational efficiency and combines the company’s technologies to deliver an industry-leading, resident ROV solution. Developed as part of a Statoil contract, the remotely operated system enables operators to intervene faster, keep production online more effectively, and perform routine tasks with fewer deployments. The system interfaces with the service company’s onshore mission support center via a 4G mobile broadband signal transmitted from a buoy on the water’s surface and eliminates the requirement for a surface vessel onsite.

The system can operate for extended periods of time without being recovered to surface. Comprising a work class electric ROV, 4G connection buoy, and subsea cage, the system reduces cost and risk.

SUBSEA WELL INTERVENTION, COMMISSIONING SYSTEM

Expro’s Next-Generation Landing String (NGLS) provides an optimal subsea well intervention and commissioning system. The new in-riser well intervention technology meets the integrity, compliance and robustness required of landing strings under the new upcoming API 17G third edition, while also delivering the time and cost efficiencies demanded. The system is comprised of a five-phase program of work to deliver a complete landing string package, including a range of new functionality across its 73/8-in. valves. It incorporates a high-debris-tolerant ball mechanism and hydraulic latch mechanism, dual-seal protection for both environment/and control systems, increased cutting capability, and a fail “as-is” retainer valve, with the ability to close after a BOP shear scenario.

The new functionality is proven through extensive connector testing and analysis, allowing the development of structural and fatigue capacities to increase the operating limits of the system.

HANDS-FREE MARINE DRILLING RISER SYSTEM

The HFRe drilling riser from Dril-Quip is an automated system designed for HPHT applications with efficient operations, incorporating SmartSpider technology. This technology provides critical feedback and eliminating rig floor personnel during installation. HFRe utilizes a boltless, fatigue-resistant 4-million lbf coupling, tested beyond API 16F/TR7 requirements.

PROCESS-AUTOMATION PLATFORM

The NOVOS reflexive drilling system is a process-automation platform from National Oilwell Varco that performs a series of actions when prompted, just as human reflexes respond to a specific stimulus. The platform manages rig equipment to execute drilling programs, allowing the driller to step back from the repetitive complexities of machine and process control. As more challenging wells continue to be drilled, drillers are having more and more difficulty handling overwhelming amounts of data needed to manage the operation, tasks in need of constant attention, and the high, necessary skill levels to achieve both performance and consistency. It addresses these issues by providing an innovative platform for the control, monitoring, scheduling and optimization of drilling operations.

The system also structures data and defines activities through process automation, enabling engineers to develop lessons learned and scale best practices across regions and rig fleets, regardless of specification.

ADAPTIVE DRILL BIT

The TerrAdapt adaptive drill bit from Baker Hughes, a GE Company, (BHGE) is touted as the first to adjust autonomously to downhole conditions, and reportedly the first drill bit to integrate intelligence and automation into the bit to enhance drilling performance and efficiency. Each bit has replaceable, self-adjusting depth-of-cut control elements installed inside the bit blades. The elements have a hydro-mechanical response tuned to mitigate dysfunction from changing loading conditions downhole. When the elements sense a rapid change in load, they automatically extend to limit further bit engagement and prevent vibrations from worsening. The extended elements also absorb any sudden shock to the bit face, significantly reducing damage to the bit’s cutters and other BHA hardware and electronics.

RESISTIVITY AND IMAGING LWD TOOL

The GeoFusion 475 Laterolog Resistivity and Imaging LWD Tool from Oliden Technology is a drilling, formation evaluation and production optimization solution. It provides high-resolution and high-measurement range array quadrant resistivities, even while sliding. Augmented by bit-resistivity and high-resolution wellbore resistivity images and azimuthal gamma images, the tool offers new solutions to drillers, petrophysicists and reservoir engineers. It is combined with an MWD tool that provides power from either battery or generator sources and sends real time telemetry to surface for a powerful upgrade to the drilling operation.

AUTOMATIC REAL-TIME ONLINE WIRE ROPE INSPECTION SYSTEM

Small business winner. The TCK.W Comprehensive Automatic Real-time Online Wire Rope Inspection System was developed by Luoyang Wire Rope Inspection Technology Co. Ltd. This technology solves the wire rope inspection need without much manpower. It can be activated by a single maintenance engineer. The new system can detect internal and external wire rope defects that consist of corrosion, broken wires, abrasion and fatigue and provide daily, weekly and monthly reports automatically. It is the latest technology developed for the purpose of automating wire rope inspection for offshore cranes.The new tool can be connected via wireless and be monitored on a normal PC at the maintenance managers' desk; freeing up report writing and communication delays.

DEEPWATER MULTI-STAGE FRACTURING SERVICE

The DEEPFRAC deepwater multi-stage fracturing service from Baker Hughes, a GE company, (BHGE) leverages stimulation technologies and techniques that have been utilized in the development of unconventional land plays and adapts them for offshore wells. Unlike conventional multi-zone completion systems that are costly, time-consuming, and restrict reservoir contact, the new service delivers an increased level of completion efficiency and flexibility. Using ball-activated multi-position sleeves and patented flow-back control technology, the service reduces steps of conventional jobs while enabling rapid stimulation of 20 or more tightly placed stages, helping operators to reduce OPEX and achieve greater, more efficient reservoir contact.

The service allows stimulation programs to be designed around natural fractures, shale bands, and/or water zones. The service’s modular sleeves allow multiple small sections to be stimulated, rather than treating a few large, evenly-spaced zones, enabling more precise delivery of fluids and proppant. ![]()

- Coiled tubing drilling’s role in the energy transition (March 2024)

- Advancing offshore decarbonization through electrification of FPSOs (March 2024)

- What's new in production (February 2024)

- Subsea technology- Corrosion monitoring: From failure to success (February 2024)

- Using data to create new completion efficiencies (February 2024)

- Digital tool kit enhances real-time decision-making to improve drilling efficiency and performance (February 2024)

- Applying ultra-deep LWD resistivity technology successfully in a SAGD operation (May 2019)

- Adoption of wireless intelligent completions advances (May 2019)

- Majors double down as takeaway crunch eases (April 2019)

- What’s new in well logging and formation evaluation (April 2019)

- Qualification of a 20,000-psi subsea BOP: A collaborative approach (February 2019)

- ConocoPhillips’ Greg Leveille sees rapid trajectory of technical advancement continuing (February 2019)