Value driven MWD delivers solution for difficult HPHT environments

Historically, advanced mud-pulse MWD systems have been inaccessible to independent directional drilling companies. But new developments by NOV in advanced directional drilling technology enable broader access by this market segment. And this technology provides cost-effective solutions to all segments of the directional drilling market.

The Tolteq Hellfire systems use configurations of iSeries NXT components that provide faster, more robust communication and better reliability in higher-temperature, higher-pressure, abrasive and vibration-prone conditions. The new components are more accurate, advanced and rugged than typical iSeries components. These configurations have some of the best directional measurement accuracy in the industry and fast, reliable pulsing. Expandable measurement capabilities create an opportunity for independent directional drilling companies to offer additional services and capabilities to their clients. And the advanced system can be customized to meet a wide variety of applications with its vibration-resistant tool string.

TOOL DEVELOPMENT

The company’s research and development scientists comprehensively reviewed and tested MWD technology for directional drilling to find a pathway to better-performing tools at lower prices. Decreasing capital requirements for commercialization and identifying methods to reduce overall system costs for end-users were also top objectives. The R&D effort led to the Hellfire advanced mud-pulse MWD system that has increased directional accuracy and overall improved drilling performance. The system’s data transmission rates are up to 400% faster than the current industry standard—enabled by leveraging advanced pulser electronics with machine-learning-driven pulse decoding. This makes additional real-time measurements possible—without additional equipment—including real-time annular, bore and differential pressure-while-drilling (PWD) measurements.

Filling a gap in previous technology, the new system transmits strong, fast pulses delivering the latest directional measurements from the drillstring tools all the way to TD—because it combines an advanced top-mount pulser with an advanced directional module and proprietary surface software. Low-cost PWD options also make it possible to calculate downhole fluid pressure and equivalent circulating density to monitor surge/swab pressure for borehole stability and hole cleaning information.

R&D also produced several significant reliability improvements. These included an improved hydraulic system, mechanical components, electronics boards and pulsers. Azimuthal gamma ray is also a key feature of the improved system. And highly efficient solenoid-driven pulsers minimize battery costs. Uniquely, all proprietary Tolteq/iSeries tools are fully designed and manufactured in-house by NOV, using the latest manufacturing techniques and design standards. Their proprietary connectors minimize risk of damage during assembly and operation. All these aspects eliminate compatibility and interface issues that have been otherwise common in the field. The improvements were made at the company’s Springett Technology Center (STC) in Navasota, Texas. The STC includes a fully operational, 375-ton, 1,500-hp land drilling rig and 31,000-ft² shop for dynamometer testing of downhole mud motors and flow loop testing of other downhole tools.

TOOL CAPACITIES

The Hellfire MWD platform is reliable, even in the harshest of conditions—which was the chief aim during development. This new system also met its other top objectives: advanced capabilities, accuracy, speed and cost effectiveness.

Heat and pressure. Each of the iSeries NXT/Hellfire and Tolteq/iSeries modules are rated to 347°F and 20,000psi—or, optionally, 25,000 psi. This provides reliable performance, even in deep HPHT applications.

Vibration. The top-mount pulser provides axial retention within the toolstring, allowing enhanced shock and vibration resistance. And it eliminates MWD string bounce at its source, avoiding additional shock absorbers or other Band-Aid solutions.

APPLICATION CUSTOMIZED

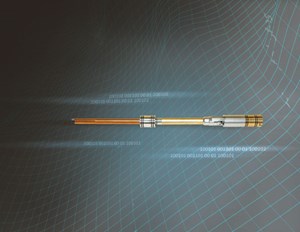

Ready-to-deploy, the customized system configuration kits (Fig. 1) are available for rental or sale for remote operations, but U.S. customers prefer to rent the equipment. System configurations can be customized to meet every application. For example, customers can customize their specific system to provide multiple optional measurement capabilities, including pressure-while-drilling (PWD), symmetric propagation resistivity and azimuthal gamma options.

Platform configuration includes several dedicated modules, each with ToolTracker preventative maintenance software. These include the advanced directional module, top-mount pulser, intelligent ruggedized gamma module, integrated one-way-connection centralizers and integrated surface equipment. Basic Hellfire system components are detailed below.

Advanced directional module. The NXT advanced directional module delivers improved inclination and azimuth accuracy. This is enabled by advanced calibration relying on a genetic algorithm, which solves for both constrained and unconstrained optimization problems, based on a natural selection process mimicking biological evolution. The tool is built with industry-proven and accepted accelerometers for enhanced accuracy without the need for complex calibration routines.

An expandable measurement suite includes 6-axis static surveys, ±0.1° inclination precision and ±0.2° azimuth precision as standard features. It also has a unique compression algorithm to minimize continuous measurement bandwidth and provide continuous measurements. Continuous inclination and azimuth specifications are ± 0.5°. This advanced directional module has proven shock and vibration resistance, smart power management and an efficient battery-switching option.

Top-mount pulser. The NXT top-mount pulser comes in 4¾-in., 6½-in. or 8-in. OD drill collar diameters, Fig. 2. It provides several key advantages over bottom-mount units. Increased flow by area creates higher tolerance for lost circulation material—up to 60 lbm/bbl. This eliminates having to use complex, failure-prone lower ends and mule shoes. Its larger poppet-orifice design delivers stronger pulses without consuming additional power. This is ideal for deep wells with high standpipe pressures and drilling agitators. Advanced driver electronics enable rapid 4.0-bps pulsing all the way to TD. And a proprietary detection algorithm enables reliable decoding without multiple transducers.

Also, widespread use of agitators in horizontal drilling applications eliminates the use of retrievable MWD systems. But this allows the design to be top-mounted, and locked-down systems make for a robust, more reliable application. This avoids an estimated 25% of MWD failures attributed to bottom-mount (retrievable) designs, which are subject to increased wear and can require additional components like shock absorbers to bolster their design. Also, top-mounted designs allow all sensors’ measurements to be closer to the bit.

Gamma module. An intelligent ruggedized gamma module (iRGM) offers extreme resistance to shock and vibration—and is rated to an industry-leading 45 G RMS for vibration exposure. This is enabled by its patent-pending floating gamma chamber that isolates fragile components from harsh external forces.

The tool’s optional azimuthal gamma is known as iAZG. The iAZG’s onboard processor provides extensive logging-while-drilling (LWD) capability and data analysis for 16 recorded sectors—with four available in real time. Sectors include temperature, vibration, shock, voltage, current and gamma count. The module also integrates seamlessly with the ToolTracker maintenance tracking system. And it is available in an azimuthal configuration.

Patented connections. Proprietary interconnecting centralizers are used for all modules. These allow installation and connection only in the correct direction, eliminating compatibility and interface issues.

Surface decoder system. The proprietary GUIDE surface system and software has been a proven, reliable iSeries MWD mud pulse decoding application. The new version adds features, such as fast-pulse configuration and decoding, Fig. 3. It detects mud pulses as short as 0.125 seconds, which enables faster two-second toolface updates. Compression algorithms enable 25% reduction in data size of certain measurements without compromising data density. Also, laptop-based decoding is enabled as an alternative to rig floor display-based decoding. And this portable system can be set up in 20 min.

Preventative maintenance software. A preventative maintenance tracking software comes with all modules. This enables users to track usage and downhole conditions on each individual module and apply condition-based maintenance programs. Maximizing its impact, monitoring data is both visually presented and archived.

Maintenance. Tool utilization is maximized by inherently easy maintenance. And flexible maintenance options ensure that customers can operate the new MWD system cost-effectively. Operators can maintain tools, themselves, using NOV’s easy-to-use, repair and maintenance (R&M) equipment and ToolTracker software. R&M training programs can be delivered at any NOV- or customer-owned facility. NOV also offers R&M remote support from their global product support team. And clients can use NOV’s R&M centers in the U.S., UAE, Colombia, Russia, Mexico, Germany and China.

CASE STUDIES

This new platform has been tested around the world. Robust, reliable performance in hotter-than-ever, challenging conditions has been the theme—and the Hellfire systems are producing good results in difficult downhole conditions.

China. Recently, the advanced MWD system performed reliably in a vertical deep gas well in the Tarim basin, within the Xinjiang region of northwestern China. This modular platform provided the operator with significant flexibility to configure and deploy the tools as needed for their unique application. Vertical gas wells are often deep and have harsh drilling conditions requiring robust downhole measurement tools. Field engineers must have reliable real time data to make informed decisions on wellbore conditions. This new system had the required vibration-resistant tools and advanced pulser technology to make that possible.

The new MWD string with top-mount pulser and positive displacement motor was selected to drill the final—and most challenging—portion. The 8½-in. bore was created, using 11.2 lbm/gal oil-based mud with 17% solids content. A maximum of 150°C was encountered, as the well was extended from 6,476 m to 7,700 m, TVD. The same MWD string was used for 388 circulating hrs in six runs without failure, including 175 hrs on a single run.

France. A geothermal energy operator directionally drilled a 5,447-m deep well with the advanced MWD system. It easily handled the HT well’s circulating temperatures of up to 185°C and harsh vibration. Prior to using Hellfire, the customer had been commissioning deep wells in abrasive formations. Vibration and static temperatures above 200°C were causing continuous, high service charges from conventional directional drilling providers for repair costs and extended rental periods.

At the time, it was difficult for field personnel to get to the rig site from other countries. Therefore, the customer internalized the directional drilling service—using their engineers to run the tools. The service provider’s technical experts assisted with the transition. Automatic filtering, large pulses and problem-free detection tool functions also helped, as did the tools’ extensive manuals and training videos. The operator easily reached TD and saved costs on directional drilling service charges.

Mexico. Once again, the advanced MWD system overcame demanding borehole conditions—this time in Veracruz, Mexico. A client assigned NOV to provide MWD and LWD equipment on two simultaneous wells. Expected conditions included high pressure of more than 18,000 psi (1,241-bar), bottomhole, and high temperature of at least 173°C static.

The deepest of the two HPHT wells was drilled to 7,714 m, TD. Encountered conditions included high vibrations and shocks, high temperatures and demanding hydraulics, with low flow in the deeper sections of the wells. Hellfire’s performance met the customer’s expectations, who specially noted its tool reliability. The advanced MWD system reduced drilling time and set new records in the field.

U.S. The MWD system has been deployed by independent and major service companies across all major basins in the U.S., including the Haynesville, Marcellus, Eagle Ford and Bakken shales, and the Permian basin. In more than 2,000 hrs of downhole operation, Hellfire configurations’ integrated PWD measurements and ruggedized features enabled superior drilling results for both typical and specialized applications. The U.S. rental business is strong, and Hellfire kits have been rented for all string sizes from 4¾-in. to 8-in.

CONCLUSION

NOV has combined innovative MWD technology with decades of downhole drilling tool experience to design, test and launch an improved version of the Tolteq system. This technology combination provides superior MWD performance with expandable LWD measurements to help small, independent directional drilling companies and larger operators improve their offerings to existing and potential clients.

This next-generation iSeries NXT/Hellfire configuration of mud pulse MWD tools is compatible with NOV’s Tolteq/iSeries platforms of directional drilling systems and its more than 600 tools. The Hellfire platform enhances iSeries probe-based mud pulse MWD capabilities and enables real-time drilling optimization for operations. It also has proven itself reliable and robust in harsh, hot, high-pressure, vibration-prone operating conditions. Existing tool fleets can now provide the additional iSeries NXT and Hellfire capabilities with minimal investment. These improvements help define the next level in reliability, low operating costs, user-friendly operation and maintenance in harsh environments.

- Drilling advances and where they’re headed (July 2024)

- Drilling advances (May 2024)

- Can an offshore drilling rig run on green methanol? (May 2024)

- Digital’s influence on drilling and production keeps growing (March 2024)

- Taming the red zone with automation (April 2024)

- Wellbay innovation supports lower-cost, lower-risk phased approach for HP DW discoveries (April 2024)