Automation & Control

Article

January

Remote-controlled FPSOs are a first step toward autonomous offshore operations once advanced solutions address significant technical gaps.

Article

Sponsored Content

January

Closed-loop automation delivers real-time control, proven return on investment, and a new global standard for hydraulic stimulation.

Article

December 2025

As the global energy landscape evolves, the Middle East remains a focal point of opportunity and complexity. For 2026, the region's upstream sector faces a dual imperative: to sustain production amid maturing reservoirs and to accelerate innovation through automation and artificial intelligence (AI).

Article

December 2025

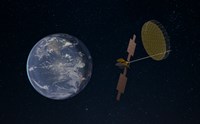

This article explores how advanced space technology and resilient satellite connectivity can support the development of autonomous oil rigs by addressing connectivity challenges in remote, hazardous environments. Improved remote monitoring, control and autonomous tools have the potential to enhance safety, increase operational efficiency and strengthen resilience across the energy sector.

News

January 08, 2026

Saronic and Hornbeck Offshore Services have formed a strategic partnership to evaluate autonomous vessel technology for offshore energy and service operations, including pilot projects and fleet applications.

Article

December 2025

This article examines Halliburton's data-driven approach to well control audits that use artificial intelligence (AI)-supported workflows, real-time data, and historical records to identify at-risk wells, streamline compliance, and reduce nonproductive time.

News

December 12, 2025

KROHNE introduces enhancements in ultrasonic flow meter verification to improve custody transfer accuracy, reduce pumping costs, and ensure API-compliant performance in oil and gas operations.

Article

November 2025

NOV discusses how real-time, digital ESP management solutions help unlock new levels of efficiency across a well’s production life cycle.

News

November 01, 2025

Hit your most critical business outcomes and metrics using advanced edge computing

News

October 27, 2025

Halliburton signed a framework agreement with Shell to deploy its ROCS umbilical-less tubing hanger system, following successful Gulf of America trials that set a new deepwater record and reduced deck operations by 75%.

News

October 20, 2025

Forum Energy Technologies’ (FET) Subsea division has secured a contract to supply two of its new-generation XLX EVO III work-class remotely operated vehicles (ROVs) to Nigerian offshore operator Marine Platforms Ltd. (MPL).

News

October 17, 2025

Rockwell Automation has released a new report highlighting artificial intelligence (AI), the Internet of Things (IoT), and cybersecurity as leading drivers of digital transformation across the global oil and gas sector.

News

October 02, 2025

Danos has acquired Panel Specialists Inc., in a deal that broadens its’ technical services footprint in Houma, Louisiana, enhancing automation, control, and reliability solutions for upstream oil and gas customers.

News

September 25, 2025

Aker BP and FourPhase have executed the first-ever remote offshore solids management operation in the North Sea. The two-month project reduced offshore exposure, improved efficiency and safety, and set a new benchmark for future digital and remote well interventions.

News

September 30, 2025

Why pump uptime isn’t the real measure of frac efficiency. True performance requires autonomous pressure control—especially in simul-frac operations—to optimize transitions, reduce downtime and deliver smarter, more meaningful gains.

News

September 22, 2025

Forum Energy Technologies has introduced ICE Unity, its advanced ROV control system designed to streamline offshore operations. The system features a unified user interface, remote monitoring, predictive maintenance, and compatibility across FET’s full ROV fleet.

News

September 10, 2025

Forum Energy Technologies (FET) has been awarded a contract to upgrade two remotely operated vehicles (ROVs) for a global vessel operator. The upgraded systems will be equipped with FET’s latest control system, ICE Unity, plus FET’s proven system architecture.

News

August 25, 2025

Ace Well Technology, in collaboration with Expro and Archer, has successfully completed the first well deployment of the Ace Control Line Clamp (ACLC) using Expro’s Remote Clamp Installation System (RCIS) on the Norwegian Continental Shelf (NCS).

News

August 18, 2025

ProFrac and Seismos have partnered to launch Closed Loop Fracturing, now available across all major U.S. basins. The collaboration marks the first large-scale deployment of an extensively operator-validated, real-time, automated quality control system.

News

August 12, 2025

Tata Consultancy Services (TCS) has secured a five-year renewal and expansion of its contract with Weatherford International. Under the extended agreement, TCS will leverage its expertise in automation, artificial intelligence, and digital optimization to drive enterprise-wide business transformation initiatives for Weatherford.

News

August 11, 2025

Expro has successfully delivered the world’s first fully remote five-plug cementing operation in Saudi Arabia. The five-plug stage-cementing operation was executed for a 9-5/8” casing run in a high-pressure gas well—the longest of its kind in the field.